What Really Matters in Packaging Decisions? Our 2025 Research Reveals the Top Priorities

At Reusable Box, we don’t just make packaging — we solve packaging problems. To better understand what matters most to our clients and the wider market, we recently conducted a large-scale insights campaign targeting procurement managers, logistics coordinators, and packaging decision-makers across multiple industries.

From healthcare and aerospace to electronics, events, and film production, one thing became clear: businesses are evolving their packaging priorities.

So, what’s at the top of the list in 2025?

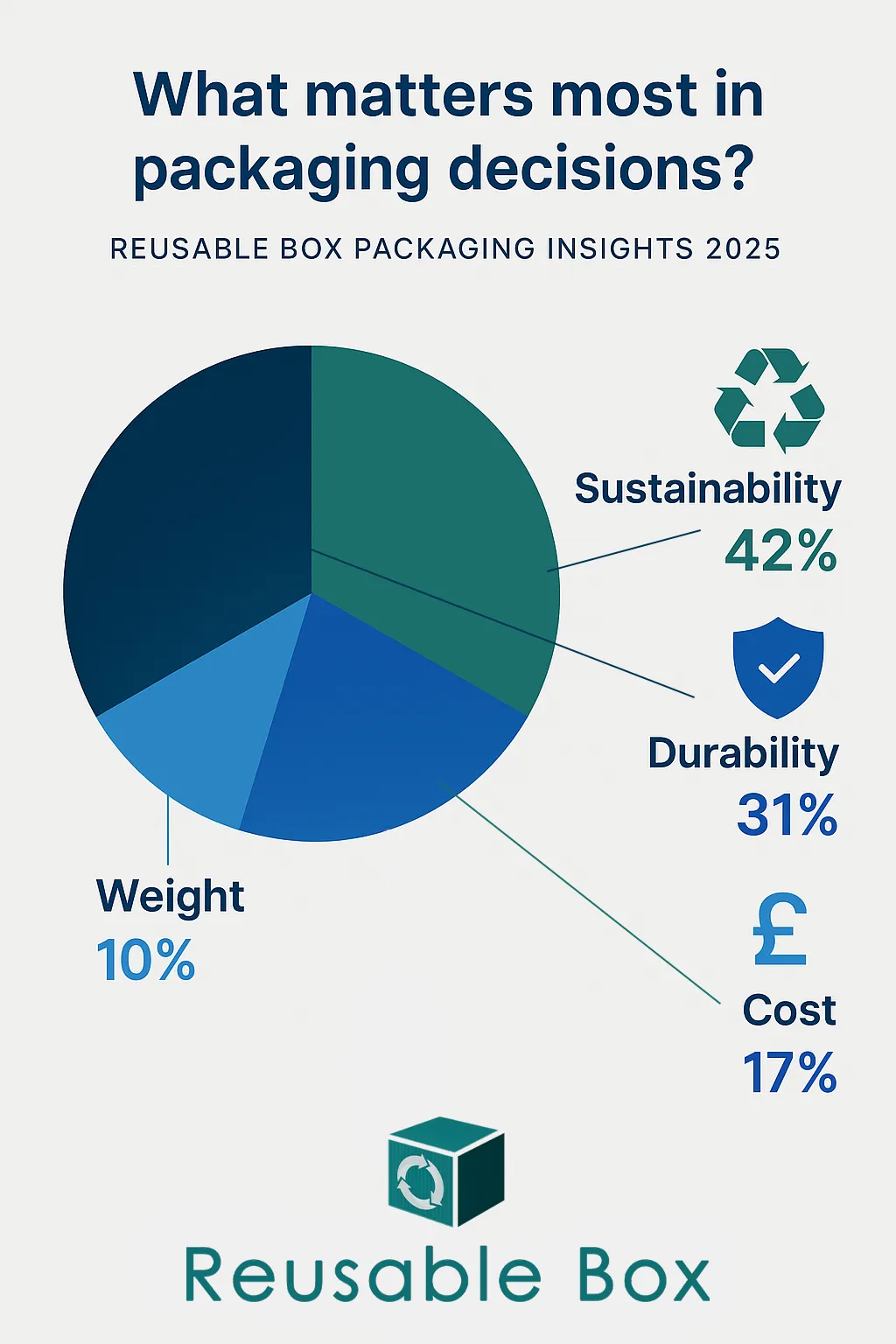

📊 The Results Are In:

Here’s how our respondents ranked the most important factors in their packaging decisions:

-

♻️ Sustainability – 42%

-

🛡️ Durability – 31%

-

💷 Cost – 17%

-

⚖️ Weight – 10%

♻️ Sustainability Takes the Lead (42%)

No surprise here. With growing ESG commitments, green supply chain goals, and rising pressure from stakeholders, sustainability has taken the top spot.

Reusable packaging offers a powerful solution:

-

Fewer single-use materials

-

Less waste generated over time

-

Longer product lifecycle

-

Fully recyclable internal components (e.g. foam inserts)

It’s clear that businesses are looking beyond the first journey — they’re designing for the long haul.

🛡️ Durability Comes in Second (31%)

Durability matters more than ever in industries with complex handling processes. From rugged transport environments to long-term storage, packaging that protects — and keeps protecting — is essential.

That’s why Reusable Box focuses on:

-

Sturdy box construction using heavy-duty materials

-

Impact-resistant foam inserts

-

Lockable lids and stackable designs

When packaging gets reused hundreds of times without failing, it becomes more than packaging — it becomes part of your workflow.

💷 Cost Still Matters (17%)

While not the top concern, cost is always part of the equation — especially in high-volume operations. But many respondents acknowledged that long-term savings are more valuable than initial cost cuts.

Reusable Box offers ROI-friendly solutions by:

-

Reducing the need for repurchasing

-

Lowering product damage and returns

-

Streamlining loading and transport times

-

Supporting tax and compliance goals related to waste reduction

⚖️ Weight Is a Factor, But Not a Deal-Breaker (10%)

Weight matters most in air freight or manual handling operations. Lighter solutions are sometimes preferable, but many customers told us they’d happily accept added weight for more durability and environmental gain.

That’s why we work to strike the balance: keeping our boxes strong but efficient, without compromising performance.

🔍 What This Means for Your Business

If you’re still relying on single-use or flimsy packaging solutions, you’re not aligned with what the market values most. Customers, stakeholders, and your team all benefit from smarter, reusable designs.

At Reusable Box, we:

-

Tailor packaging to your product

-

Design with industry-specific demands in mind

-

Offer expert advice on reusability, sustainability and logistics

-

Manufacture right here in the UK

📞 Want Packaging That Ticks All the Boxes?

Let’s create a packaging system that protects your product, your reputation, and your planet.

👉 Talk to us now or explore our solutions at www.reusablebox.net

Case Study: Bespoke Two-Tiered Reusable Box for Almac Pharmaceuticals

Case Study: Bespoke Two-Tiered Reusable Box for Almac Pharmaceuticals

Client: Almac Pharmaceuticals

Sector: Medical & Scientific

Location: Global Operations, Headquartered in Northern Ireland

Overview

Almac Pharmaceuticals, a global leader in pharmaceutical development and manufacturing, approached ReusableBox.net with a packaging challenge. They needed a reliable, reusable solution for transporting sensitive eye drop products equipped with Escort Data Loggers, ensuring both product safety and logistical efficiency.

Challenge

Almac’s logistics team required a packaging solution that could:

-

Securely hold Escort Loggers for temperature-sensitive eye drops

-

Accommodate multiple units while maintaining order and protection

-

Allow for easy return and reuse, in line with their sustainability initiatives

-

Withstand repeated handling through global distribution networks

Standard off-the-shelf packaging was falling short, especially in maintaining product orientation and preventing movement in transit.

Our Solution

We designed and manufactured a custom two-tiered reusable box tailored to Almac’s specific product and handling needs:

Tier 1: Custom Foam Insert for Escort Loggers

-

Precision-cut high-density foam to snugly fit and protect Escort Data Loggers

-

Eye drop containers nestled individually to prevent damage or shifting

-

Easy access design for efficient loading and unloading

Tier 2: Compartment for Boxed Items

-

The second layer was engineered to hold boxed batches of the same products

-

Rigid dividers and stabilisers ensured all items remained secure during transit

-

Layered structure allowed easy separation of monitored and bulk product components

Material & Sustainability

-

Durable plastic outer shell designed for long-term reuse

-

Fully returnable packaging, reducing waste and improving carbon footprint

-

Designed for easy cleaning and sanitisation between cycles

Results

-

Improved Protection: The custom foam prevented movement, protecting sensitive equipment and maintaining calibration integrity.

-

Streamlined Handling: Two-tier design simplified the packing process and product segregation.

-

Cost Efficiency: Reusability reduced Almac’s need for single-use packaging, driving down long-term costs.

-

Sustainability Win: The returnable nature of the boxes aligned with Almac’s green initiatives and reduced packaging waste significantly.

Testimonial

“The reusable solution provided by ReusableBox.net transformed the way we package and transport this product line. It’s secure, robust, and aligns with our ongoing sustainability goals.”

— Logistics Coordinator, Almac Pharmaceuticals

5 Ways Marketing Teams Use Reusable Boxes for Campaign Logistics

Intro:

Marketing campaigns don’t just live in spreadsheets—they live in warehouses, vans, event tents, and retail displays. Behind every successful brand activation or merchandise drop is a team juggling logistics, deadlines, and assets. One tool marketing teams increasingly rely on? Reusable plastic storage boxes.

Strong, stackable, and easy to label, these boxes help streamline campaign logistics from end to end. Whether you’re packing event kits, shipping POS displays, or organising merchandise stock, here are five real-world ways reusable boxes are making life easier for marketing teams across the UK.

✅ 1. Preparing Event Kits & Sampling Packs

Whether it’s a product launch, a conference giveaway, or a field marketing activation, pre-packed kits help teams deliver consistency across locations.

Reusable boxes are ideal for:

-

Pre-loading event packs with leaflets, merchandise, and signage

-

Ensuring every box contains the same quantity of items

-

Reducing setup time by allowing team members to grab and go

-

Protecting fragile or high-value materials during transit

Reusable boxes are especially helpful for roadshows, where consistent packing and repacking is key to a seamless rollout across multiple venues.

✅ 2. POS & Display Storage

Point-of-sale materials—like plinths, signage, shelf wobblers or demo stands—often need protection and organisation between uses.

With reusable boxes, you can:

-

Prevent scuffing or bending of display boards

-

Keep all components (e.g. clamps, bases, signage) together in one box

-

Use internal dividers or foam inserts for delicate parts

-

Easily label boxes by campaign or store region

This means faster turnaround between setups and a professional presentation every time.

✅ 3. Merchandise Fulfilment Centres

Agencies and brands often run fulfilment operations from warehouses or temporary spaces. Standardised plastic boxes help improve efficiency by:

-

Stacking neatly on shelves or pallets

-

Making picking and packing easier and faster

-

Colour-coding by client, region, or campaign

-

Holding up better under frequent use than cardboard cartons

Over time, reusable boxes reduce packing waste and make your stockroom or fulfilment hub more organised and scalable.

✅ 4. On-Tour Activation Kits

When you’re taking a brand on tour—whether across campuses, shopping centres or trade shows—durability and repeatability matter.

Reusable boxes let teams:

-

Pack up once and reuse the same setup in every city

-

Fit boxes consistently in vans, trolleys or flight cases

-

Survive rain, steps, forklifts and tight loading zones

-

Repurpose the same storage for returns or leftover stock

Bonus: the uniform design helps your team look more professional and organised to clients and crowds alike.

✅ 5. Internal Office or Marketing Department Storage

Not every campaign ends with a giveaway—often you have leftover merch or re-usable display items that need storing until next time.

Use reusable boxes to:

-

Store excess branded items for future use

-

Label boxes by campaign, year, or target market

-

Protect soft goods (like t-shirts or bags) from dust and damp

-

Easily transport samples to meetings or pitch events

This turns chaotic closets into a structured marketing storeroom.

✅ Final Thoughts

From the warehouse to the roadshow, reusable plastic boxes are a behind-the-scenes hero of modern marketing. They simplify logistics, reduce damage, and keep everything campaign-ready—again and again.