New Tech, Sharper Results

New Tech, Sharper Results: Introducing Our DYSS X7 Digital Cutter

At Reusable Box, we’re always looking for ways to push quality, speed, and sustainability forward. That’s why we’ve just added the DYSS X7 Digital Cutting System to our workshop — and it’s a game-changer for custom packaging.

Whether we’re building precision transport boxes for medical equipment or developing collapsible solutions for high-end scale models, our new cutting machine means even more accuracy, flexibility, and efficiency for our clients.

What Is the DYSS X7?

The DYSS X7 is a versatile digital cutting system, designed to process a wide variety of materials with razor-sharp accuracy — from corrugated plastic and foam inserts to cardboard, vinyl, and beyond.

It uses advanced routing, kiss-cutting, and creasing tools, allowing us to create complex parts, internal foam layouts, and folding designs faster and cleaner than ever before.

Why It Matters to Our Clients

Here’s how this upgrade benefits the businesses we serve:

-

Faster Turnarounds – Quicker setup and production mean we can meet tighter deadlines

-

Unmatched Precision – Every cut, every slot, every panel edge is clean and perfectly aligned

-

Material Efficiency – Less waste, better yield, and smarter layout planning

-

Prototyping Made Easy – We can now quickly mock up sample designs before full production

-

Complex Inserts? No Problem. – Intricate foam layouts for delicate items like instruments, electronics or collector items are now easier to produce at scale

Stronger Capability, Same Custom Focus

This machine strengthens what we already do best: bespoke, sustainable, reusable packaging.

From one-off custom builds to full repeatable runs, the DYSS X7 allows us to stay lean, flexible, and fiercely quality-driven — whether we’re producing 5 boxes or 500.

📦 Have a tricky product to ship or store?

We’re now better equipped than ever to design your perfect solution.

📩 Get in touch and let’s build something clever.

Smart Shipping for High-End Scale Models

Precision Meets Sustainability: A Collapsible Transport Box for High-End Scale Models

When a manufacturer of high-end scale models approached Reusable Box, they brought a unique packaging challenge:

How do you safely ship a luxury-scale model worth thousands of pounds while staying aligned with sustainability goals — and keeping return logistics affordable?

The answer: a fully collapsible, reusable transport box engineered for both protection and practicality.

The Challenge

This client produces extremely detailed, handcrafted replicas, with each model priced in the five-figure range.

Every item is a collector’s piece — fragile, valuable, and irreplaceable.

They needed packaging that could:

-

Guarantee safe delivery to international customers

-

Reflect their brand’s sustainability focus

-

Be returned cost-effectively for reuse

Our Solution

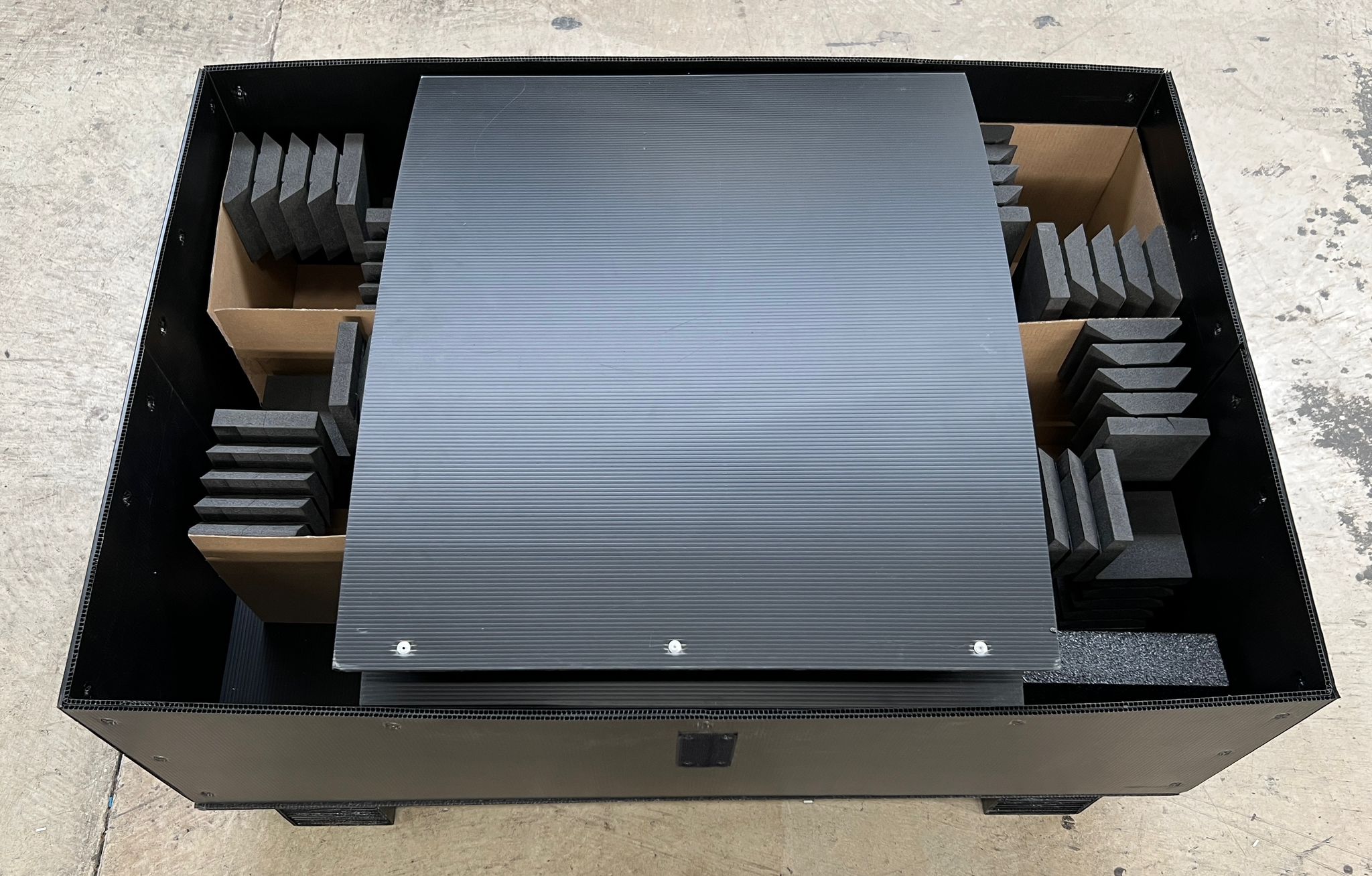

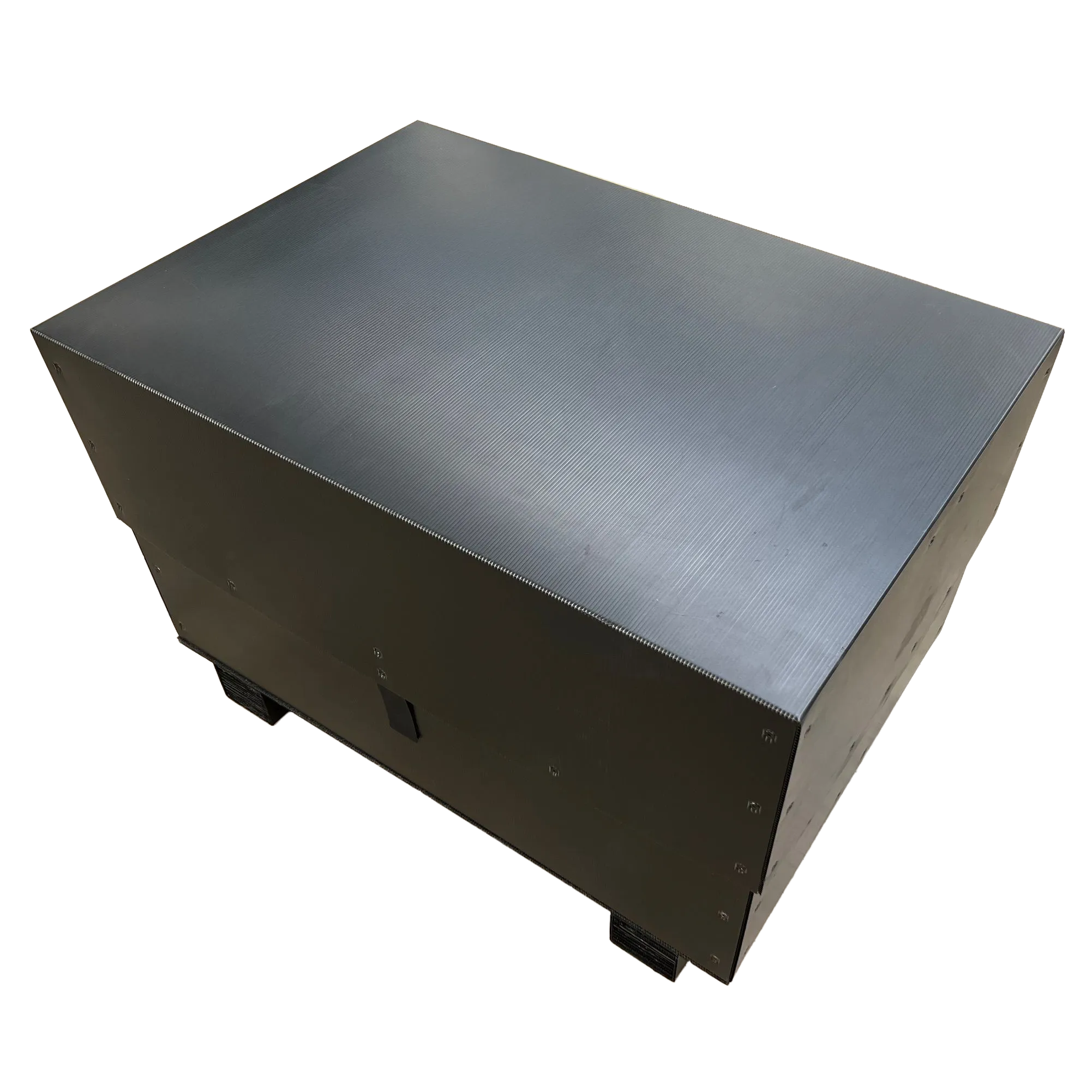

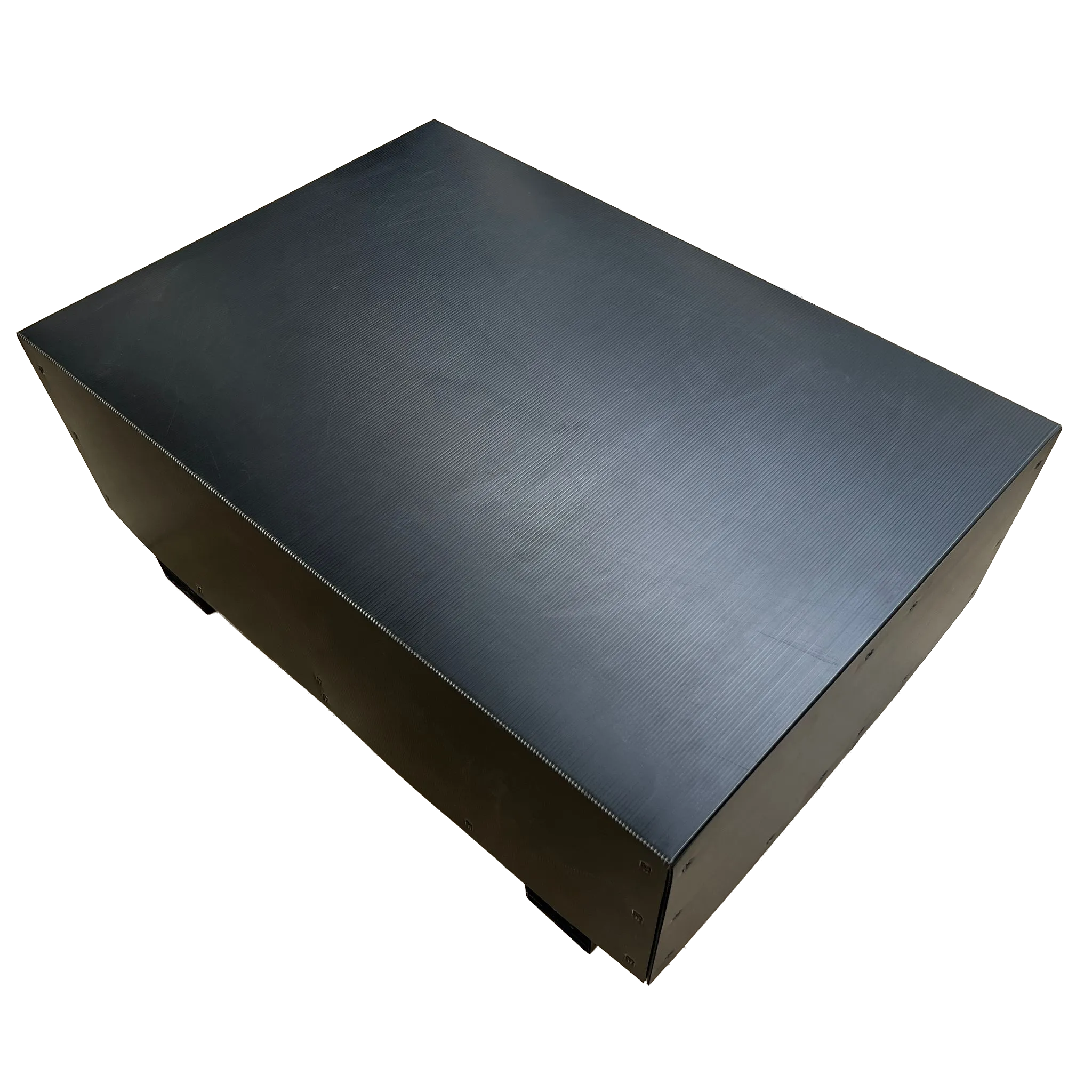

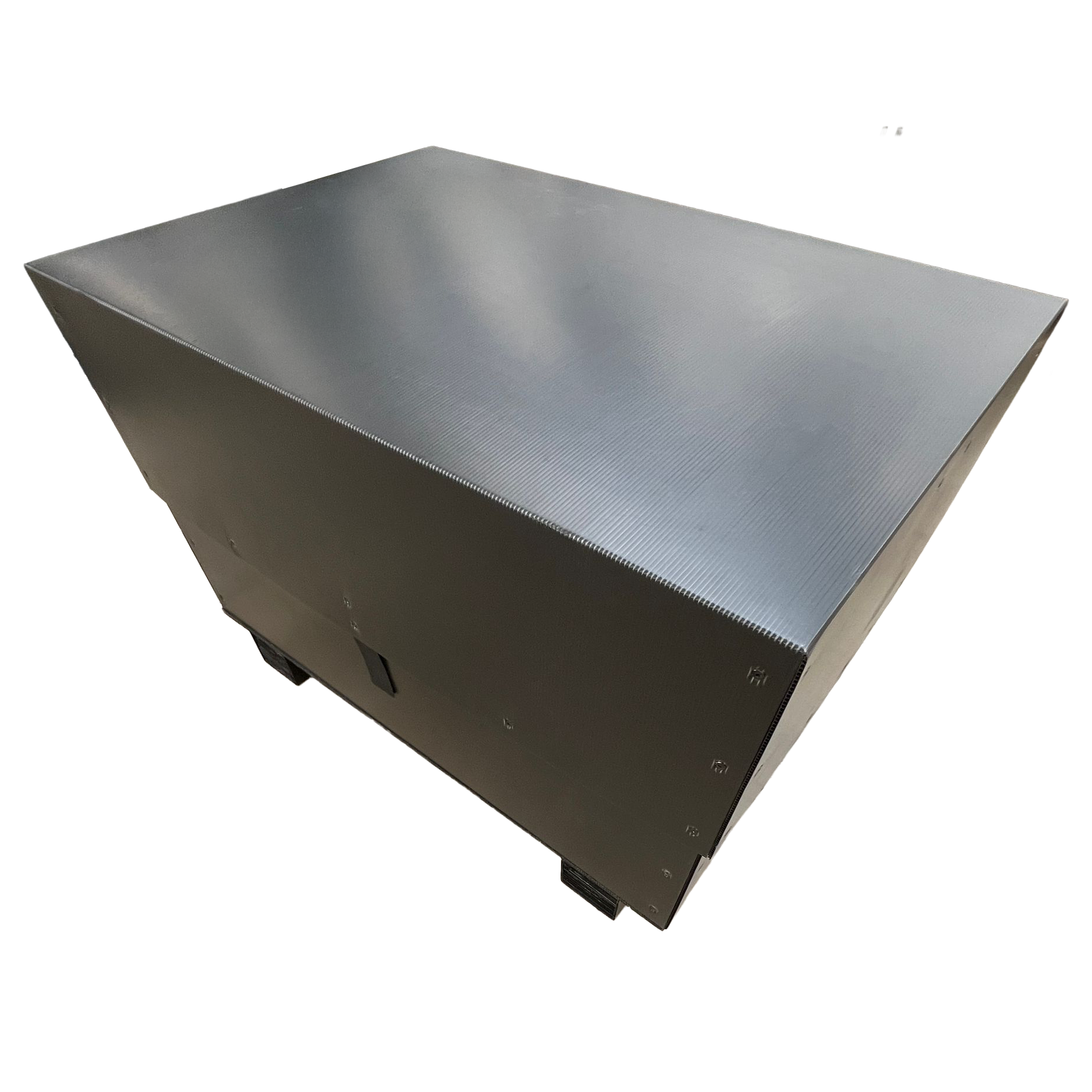

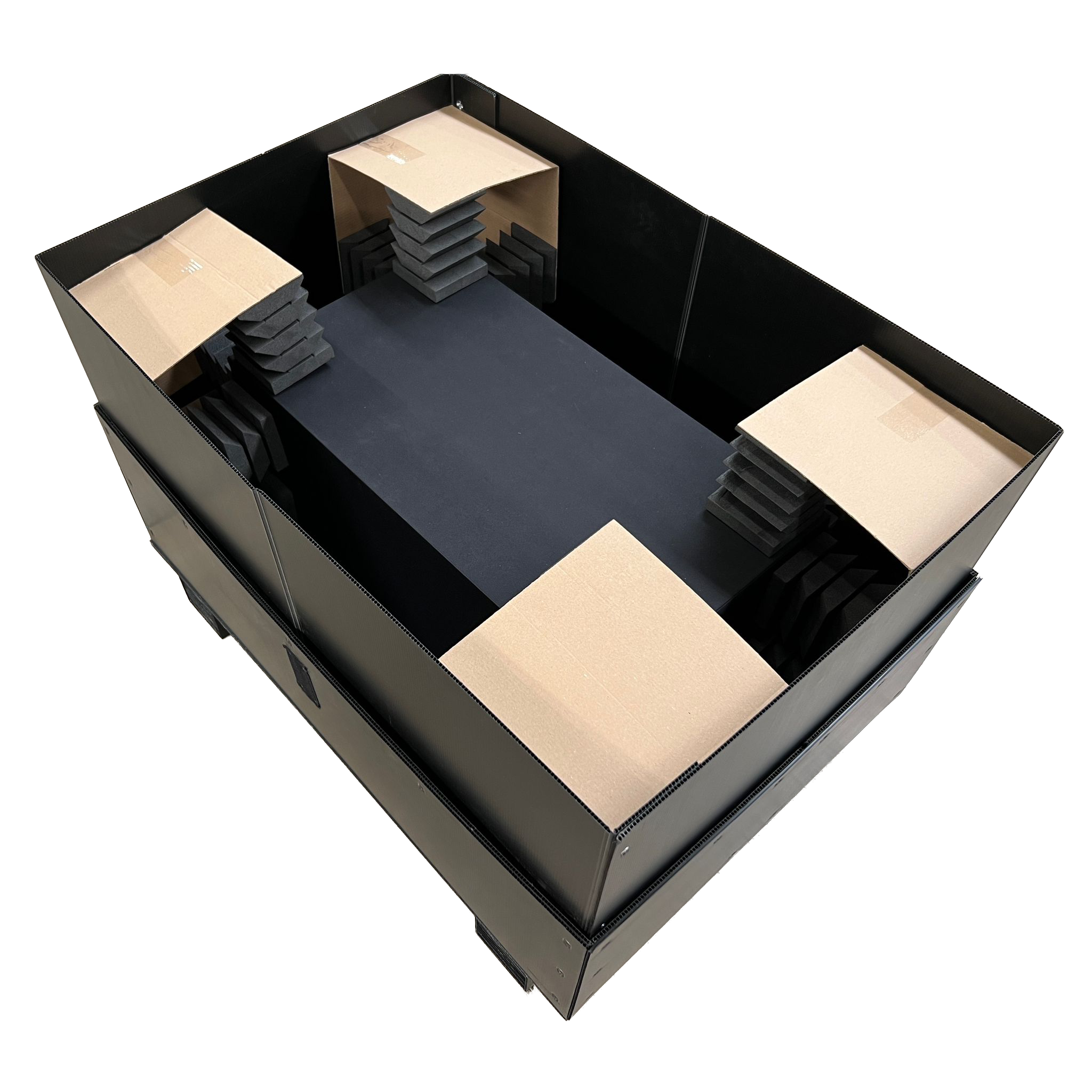

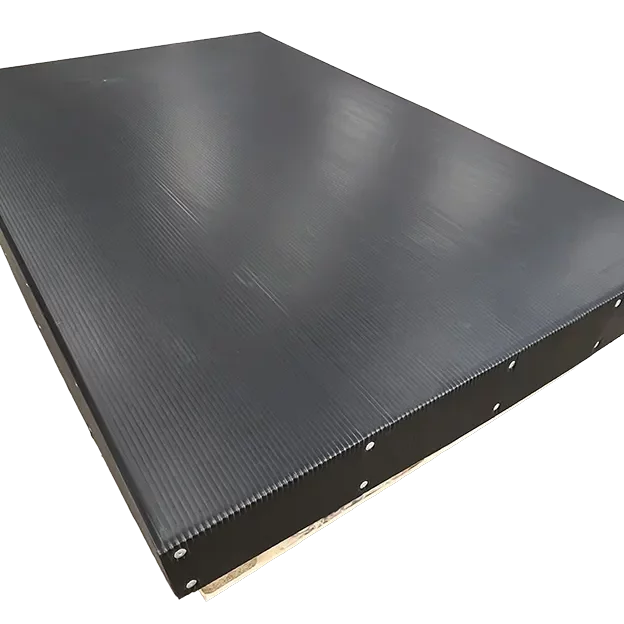

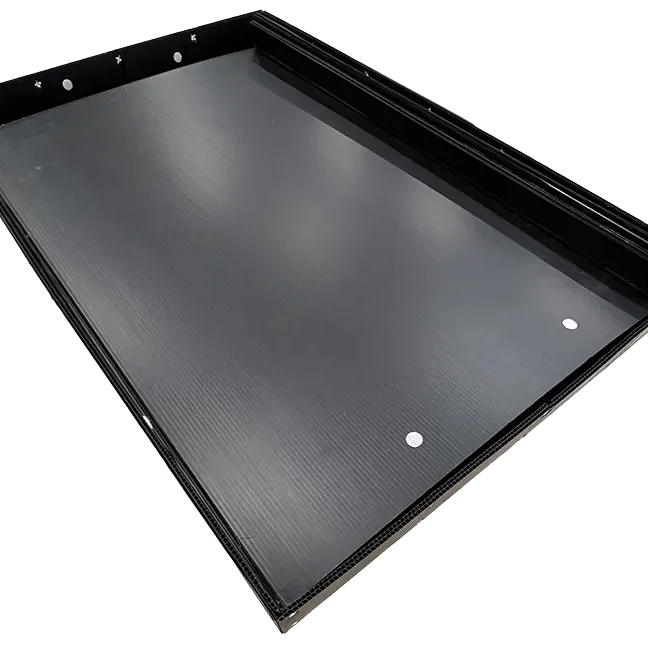

We developed a custom transport box using robust corrugated plastic panels with laser-cut internal foam inserts, tailored to the shape of each model.

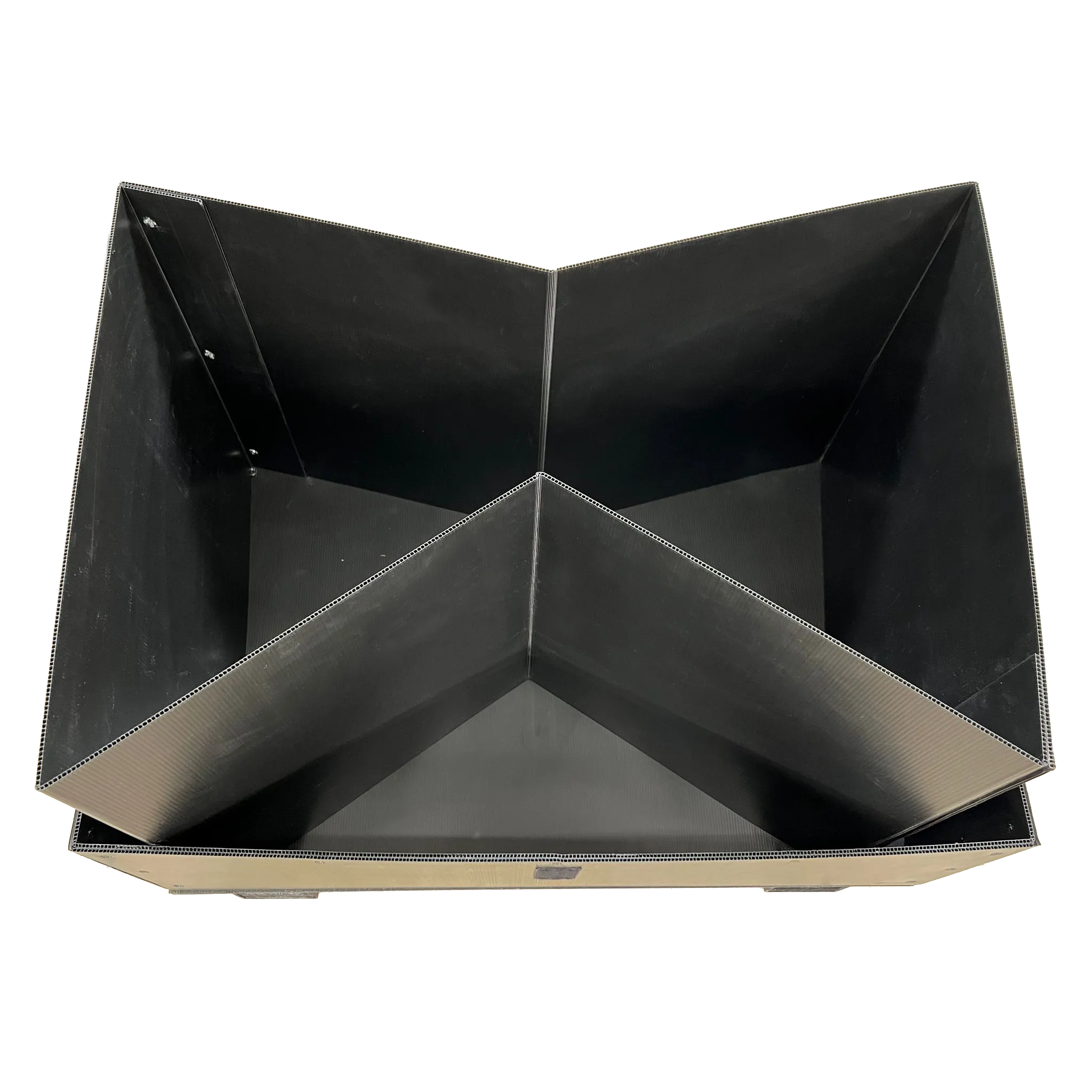

To solve the return issue, we engineered the box to be collapsible after use.

Once the model is removed, the recipient can easily fold the box down, reducing its size by over 60%.

The return trip becomes lighter, smaller, and cheaper — while the box lives on for multiple deliveries.

Key features include:

-

Printed fold-down instructions inside the lid

-

Secure Velcro straps and locking tabs

-

Lightweight, rigid construction that protects on outbound and return legs

The Result

✅ Safe, damage-free global shipping of high-value models

✅ Dramatic reduction in return shipping costs

✅ A durable, reusable system aligned with eco-conscious branding

This project is a perfect example of how thoughtful design can balance logistics, sustainability, and customer experience — all in one smart package.

Need a smarter way to ship high-value items?

📩 Get in touch — we’ll build your perfect box.