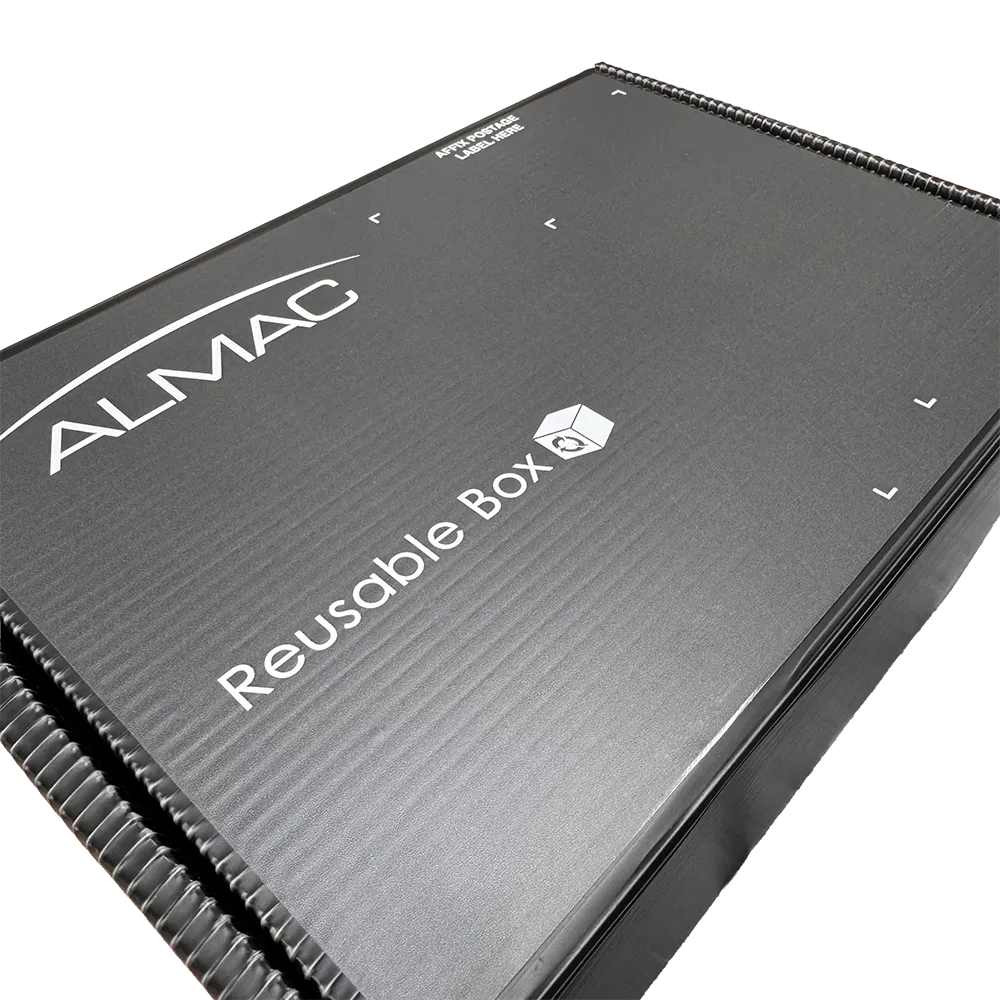

Building Three Custom Reusable Boxes for Almac Pharma

Flexible. Secure. Built for daily movement across a busy pharmaceutical environment.

When Almac Pharmaceuticals approached us, the brief was intentionally loose. They had already used a previous version of our reusable box on site and loved how robust and reliable it was for day to day movement. This time they wanted something more versatile. Instead of one box for one job, they wanted a small family of reusable boxes that could support a wide range of internal transfers across departments, buildings and specialised work areas.

So we designed three different sized boxes with matching foam cushioned inserts for general purpose use throughout their facility.

A Modular Set for Every Task

Pharmaceutical workflows never stand still. Instruments move between labs, testing areas, offices, cleanrooms and storage locations all day long. While the items can change, the demands stay the same: protect the contents, keep everything traceable and make transfers as efficient as possible.

Our solution was to create:

-

A small case for compact instruments, handheld devices and delicate items

-

A medium case for mid sized equipment and testing components

-

A large case built to handle bulkier or multi part items without compromising protection or weight

Each size follows the same structural design so staff can immediately recognise and use them in any department.

Foam Cushioned Inserts for a Flexible Payload

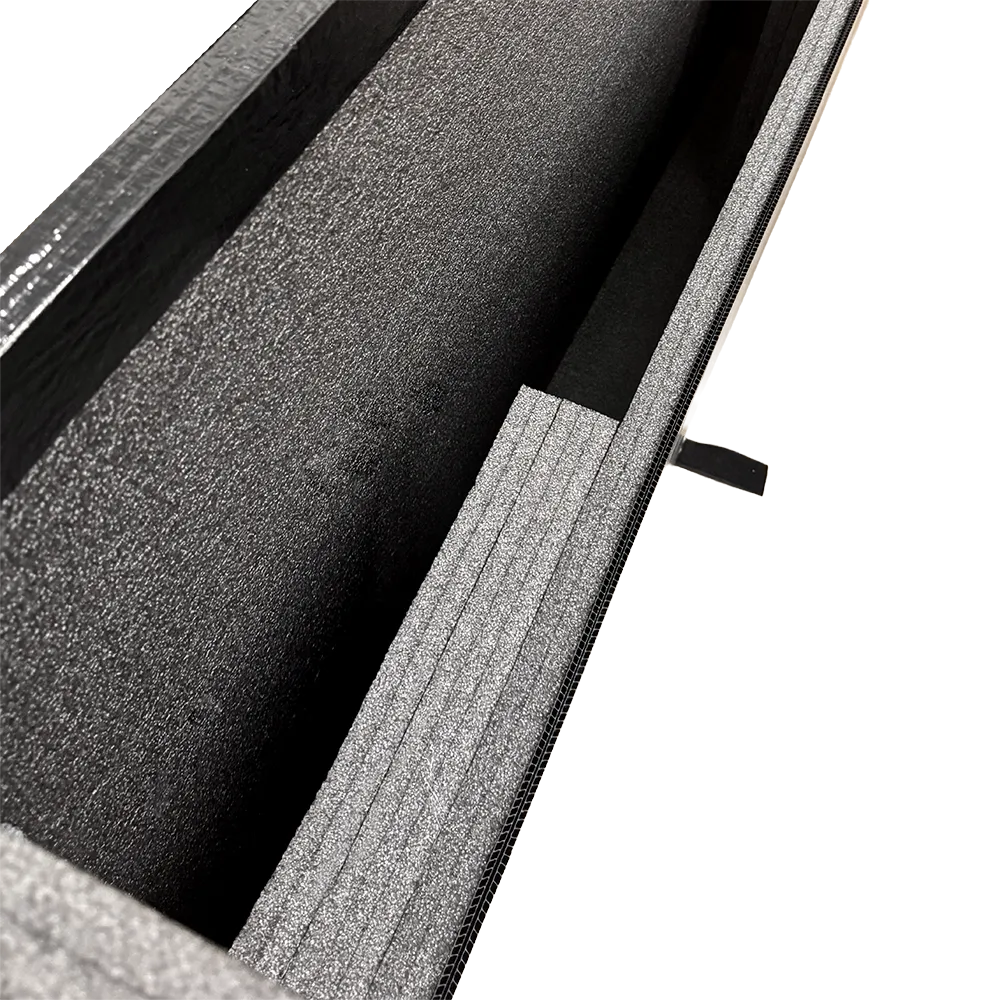

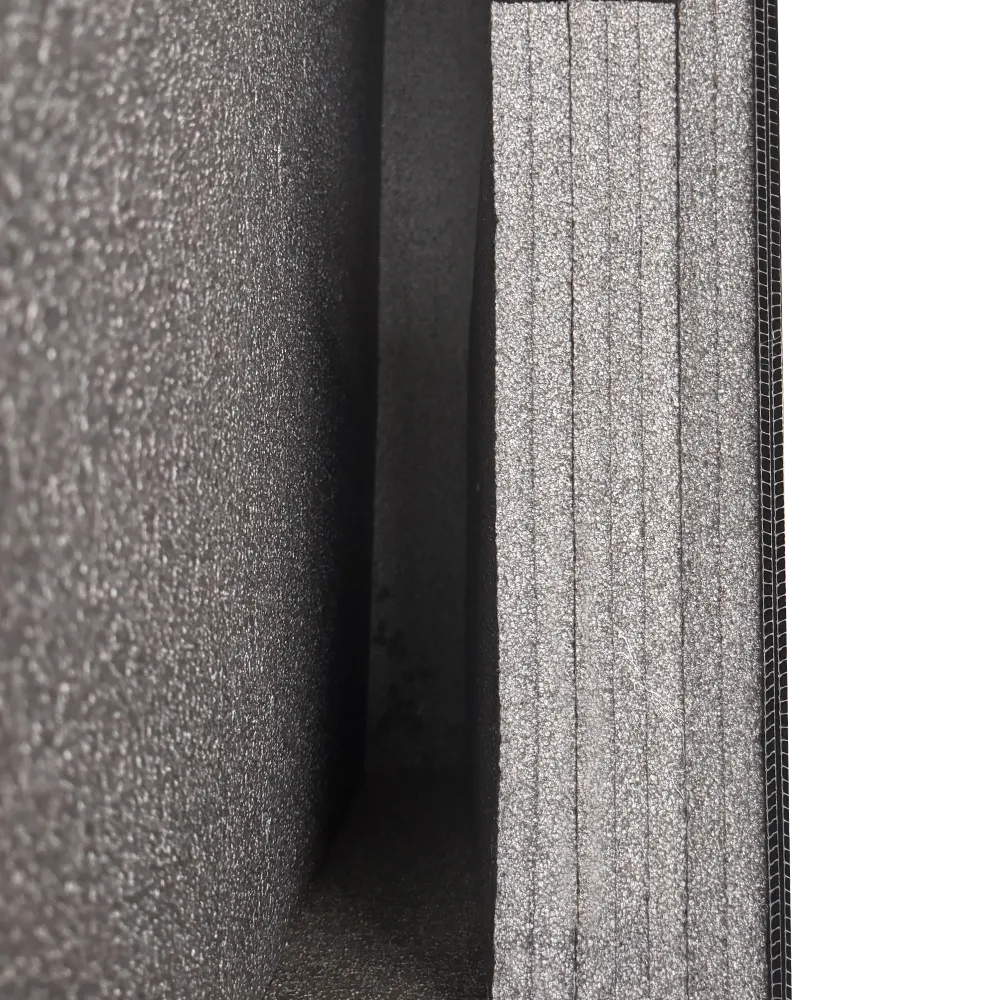

Because Almac needed these boxes for general purpose use, the inserts had to work for many different instruments. Instead of fixed cut outs, we engineered a foam system that gives protection without limiting the shape or size of the payload.

Our 30kg/m³ foam in flexible thicknesses creates a cushioned environment that keeps sensitive items safe during hand carry transfers or trolley movement between buildings.

Security Built Into the Design

Moving instruments inside a busy pharmaceutical environment means security and chain of custody is crucial. Each box includes dedicated locking points for cable ties, allowing staff to seal units quickly and clearly before transfer.

Once the box reaches its destination, the receiving team can confirm that the tie is intact, remove it and continue their workflow with confidence.

Durable and Reusable Across Facilities

All three boxes are built using our heavy duty corrugated polypropylene. It is lightweight, robust and totally water resistant so it stands up to the exact kind of internal transfers pharmaceutical teams carry out every day. From lab corridors to external walkways between buildings, these boxes are designed to last year after year.

A Simple Brief Turned Into a Complete Multi Box Solution

Almac gave us the freedom to design something practical and universal, and the result is a family of reusable boxes that slot seamlessly into their day to day processes. Whether the task is small, medium or large, they now have a consistent protective system that boosts efficiency and safety across their site.

If your organisation needs a similar internal movement solution or a customised version for a specialist workflow, Reusable Box can design it from the ground up.

'The Impossible Box’

Building the ‘Impossible’ Reusable Box for GSE’s 75 Inch Screens

When GSE in America approached us with a challenge to build a reusable box that could safely transport two 75 inch rental screens, we knew straight away this was no ordinary build. These are huge displays with huge value riding on them. They also needed a solution that was lightweight, strong, shock absorbent, and reusable across multiple hire cycles. A flight case wasn’t suitable and a wooden crate wasn’t practical. What they needed felt like the impossible dream

a reusable box big enough, strong enough, and smart enough to do the job.

So we built it.

To give a sense of scale we even placed a standard 24 inch monitor at the front when we took the photos. It looks like a toy. That is how big this project really is.

From Impossible to Engineered Reality

The first obstacle was size. A single 75 inch screen is large enough. Two screens packed together in one reusable system pushed the design to the edge of what corrugated polypropylene construction can handle. The structure had to remain rigid and square even when empty and still be manageable for the rental teams lifting and loading it.

The second challenge was protection. GSE ship high value screens constantly across events and installations. Their kit gets moved by crews under serious time pressure. The box had to survive being pushed

pulled

slid

manhandled

and still protect the contents.

That meant a multi zone foam layout with a floating centre divide, pressure rated sidewalls, a dual depth foam base, and enough shock absorption to cope with hard landings without adding unnecessary bulk.

Designing the Internal Foam System

Inside the box is where the real engineering sits. The foam system is built from multiple layers of 30 kg foam, all precision cut to form a tight structural cradle. There are three key parts:

-

The centre divide that keeps both screens separated and locked in place

-

Sidewall blocks that take lateral impact

-

Base supports that distribute weight evenly

-

Top compression layer that closes the internal system and prevents movement during shipment

Every piece is removable, replaceable, and designed for the realities of rental life.

This is a box that gets used

not admired on a shelf.

Strength Without Weight

We used heavy duty black 10 mm polypropylene for the outer structure, reinforced with both mechanical fixings and internal returns. When you walk around it you realise this isn’t a typical reusable box. It behaves closer to a fully engineered crate while staying lightweight enough for two people to handle.

The side handles, reinforced corners, and pull tabs mean that even though it’s huge, it stays practical in the field.

A Giant in the Workshop

When the prototype stood up in the workshop for the first time it genuinely felt monumental. Everyone who walked past stopped. It is rare for a packaging project to become a talking point

but this one did.

That is why we deliberately photographed it beside a standard 24 inch monitor. It helps people understand the scale of what we were building. You don’t often see a reusable box that towers over desks.

Why GSE Chose Reusable Box

GSE needed:

-

A long lasting solution

-

Better protection than wood or flight cases

-

Weight savings for easier handling

-

Something that could be repaired or re foamed over time

-

A box that could be shipped repeatedly without fail

We delivered all of that while keeping it fully recyclable at end of life.

The Outcome

The final product represents everything reusable packaging should be. Purpose built. Over engineered where it matters. Lightweight where possible. Repairable. Sustainable. And capable of doing what most people would say is impossible.

That’s the part we’re proud of.

This wasn’t just another job

this was solving a problem that no standard case or crate could solve. A reusable box for two monster sized screens that will now travel coast to coast across America with GSE’s rental fleet.

And it all started as the impossible dream.