Vyta - IT Lifecycle Solutions

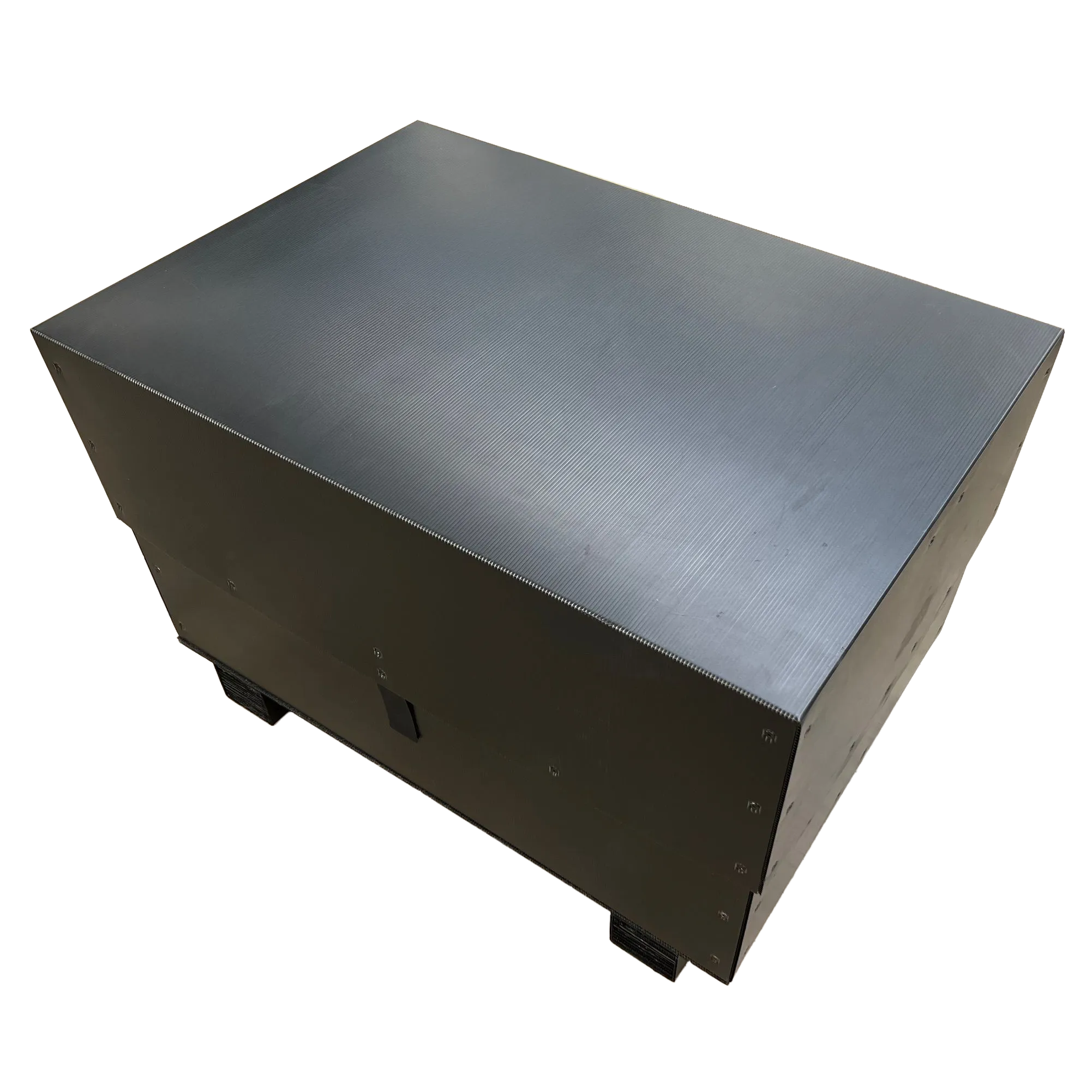

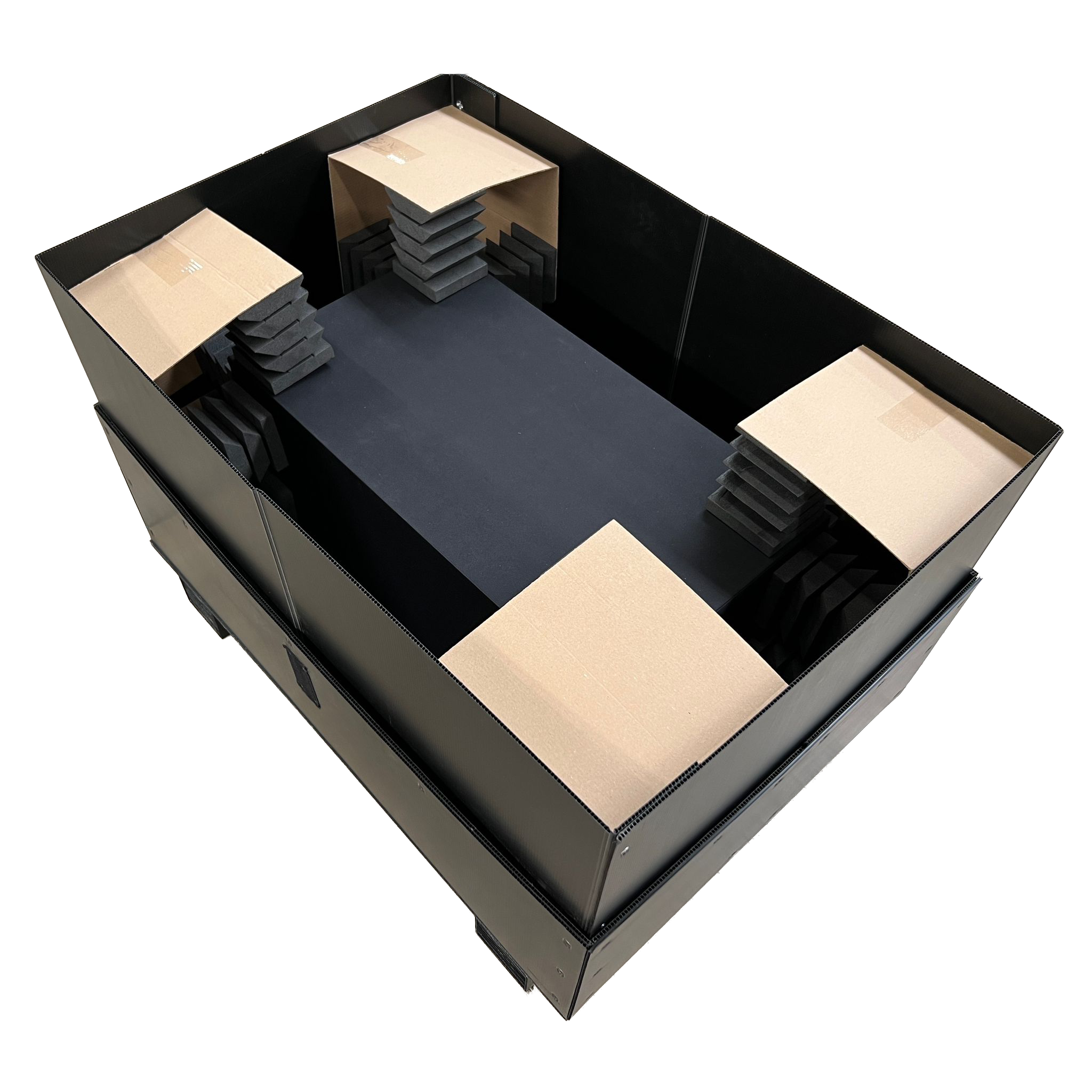

Case Study: Custom Reusable Laptop Storage Boxes for Vyta

When Vyta needed a smarter way to store and transport laptops, cardboard simply wasn’t going to cut it.

Vyta works at the sharp end of IT lifecycle management and secure data destruction. That means high volumes of laptops moving through facilities, across sites and into secure processing environments. Protection, organisation and repeat use are not luxuries. They are operational essentials.

That is where Reusable Box stepped in.

The Brief

Vyta required a durable, stackable and long term storage solution for housing multiple laptops safely in transit and storage.

The boxes needed to:

-

Protect valuable IT assets

-

Withstand repeated handling

-

Stack securely without collapse

-

Offer easy handling for teams on site

-

Maintain a clean, professional branded finish

This was not a one use packaging job. This was infrastructure.

Our Approach

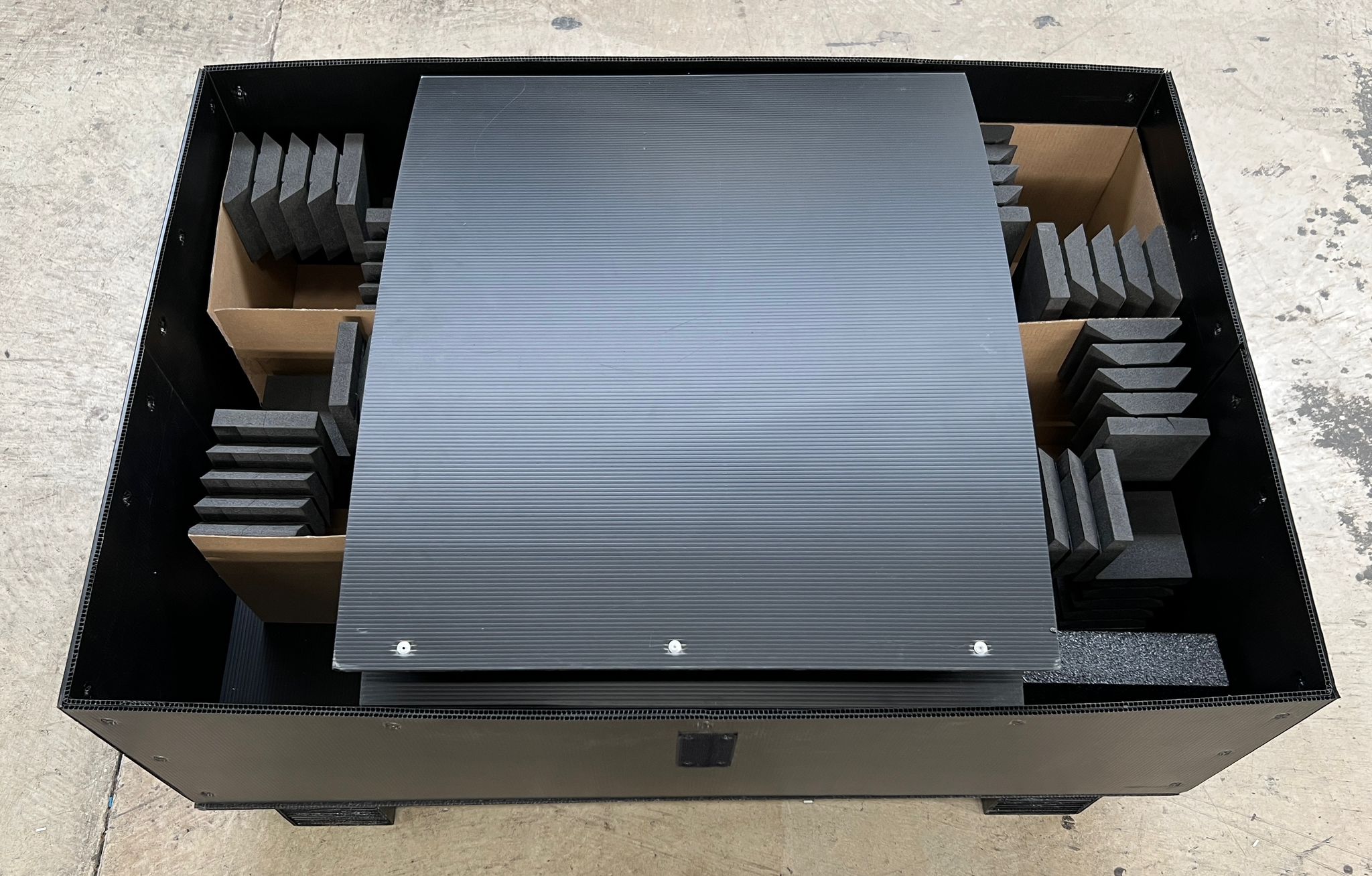

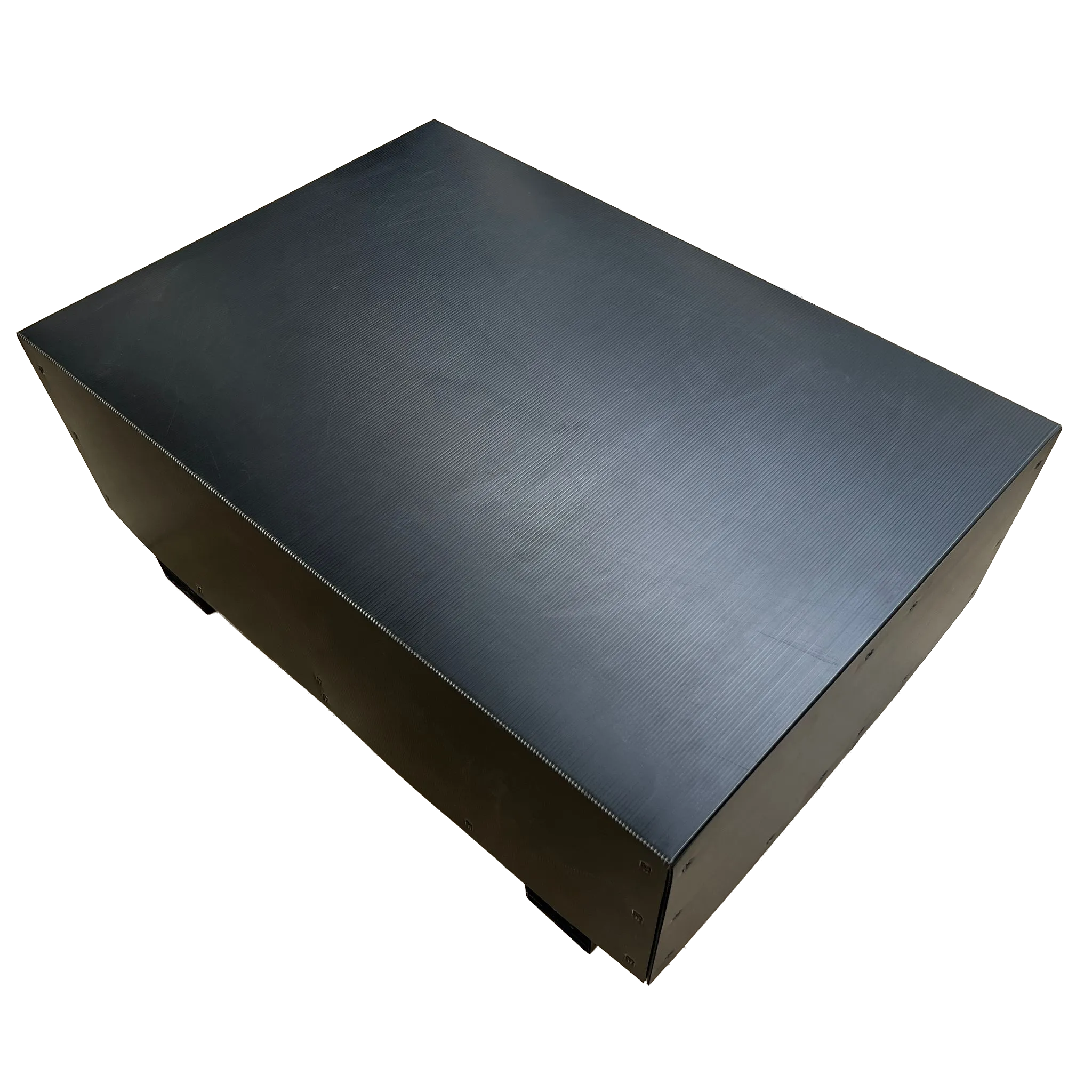

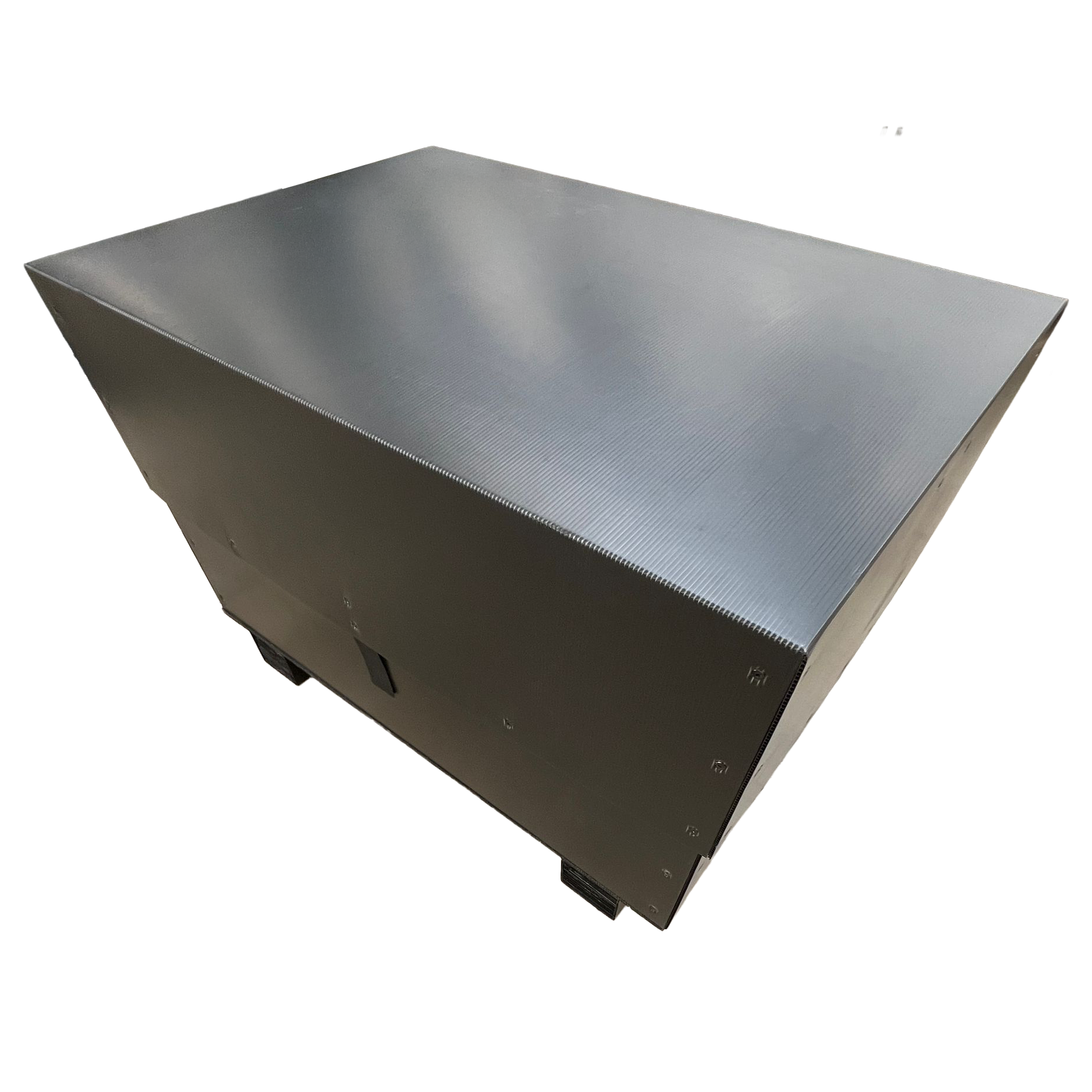

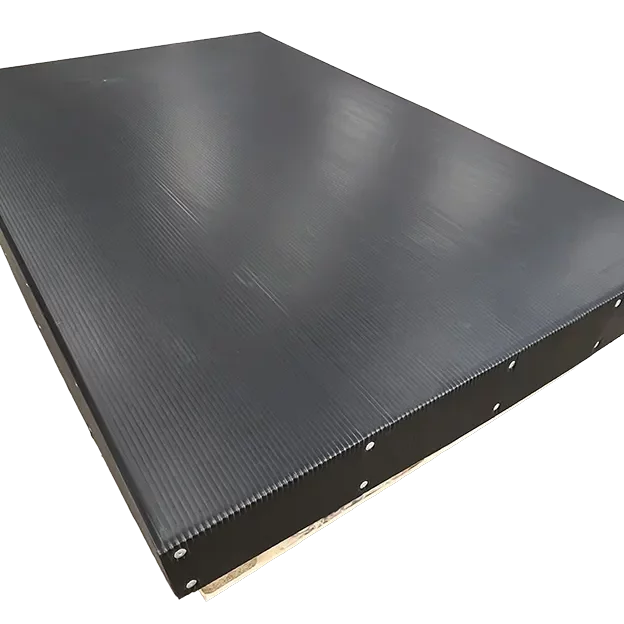

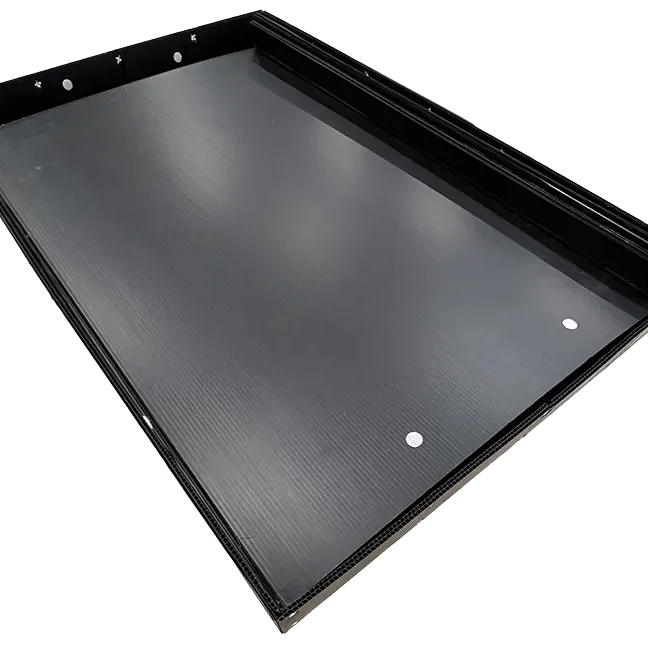

We designed a fully bespoke reusable corrugated plastic box built for strength and repetition.

Key Features:

-

Heavy duty corrugated plastic construction

-

Reinforced riveted corners for structural integrity

-

Integrated carry handles for easy lifting

-

Secure lid with fastening system

-

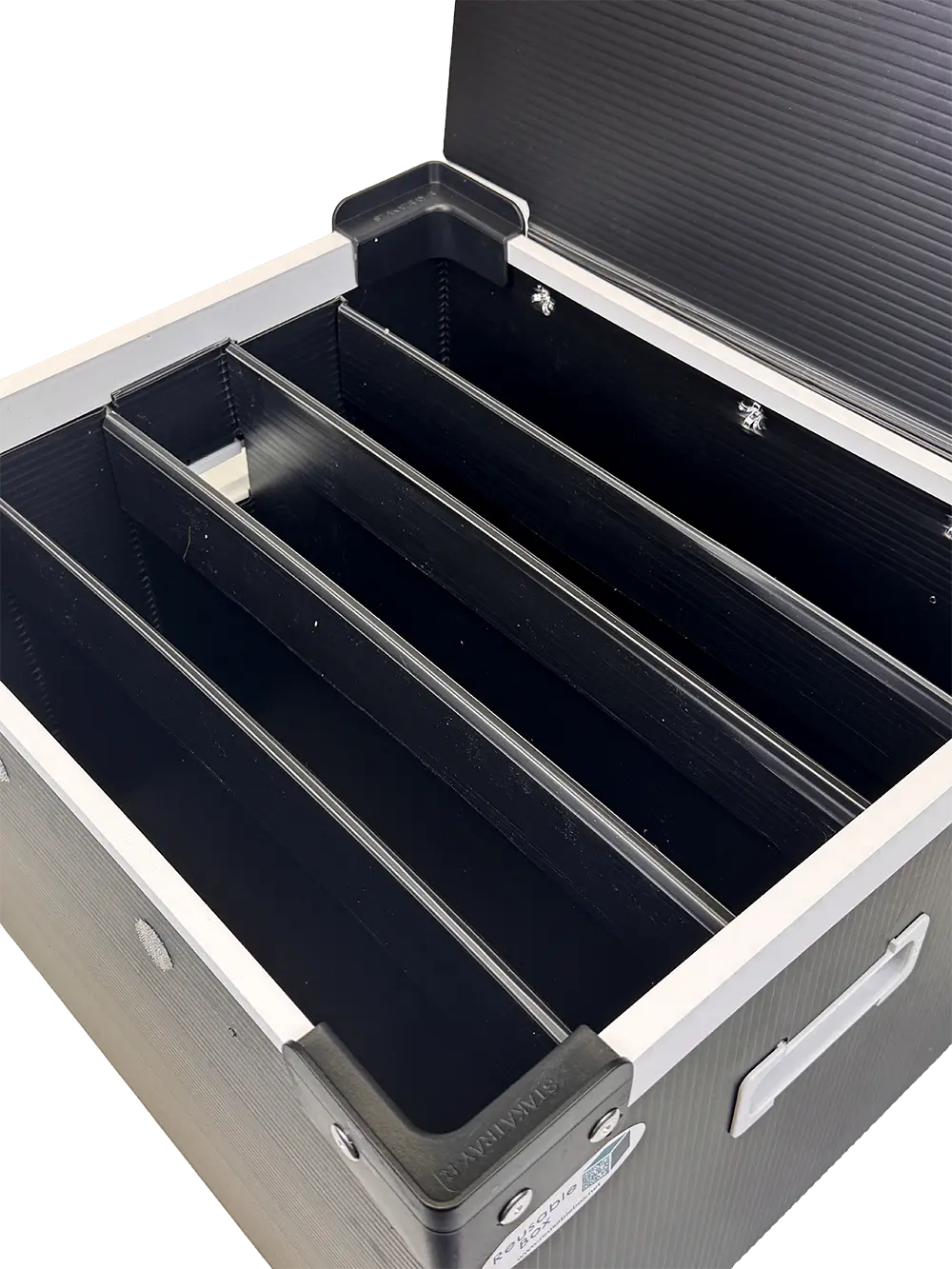

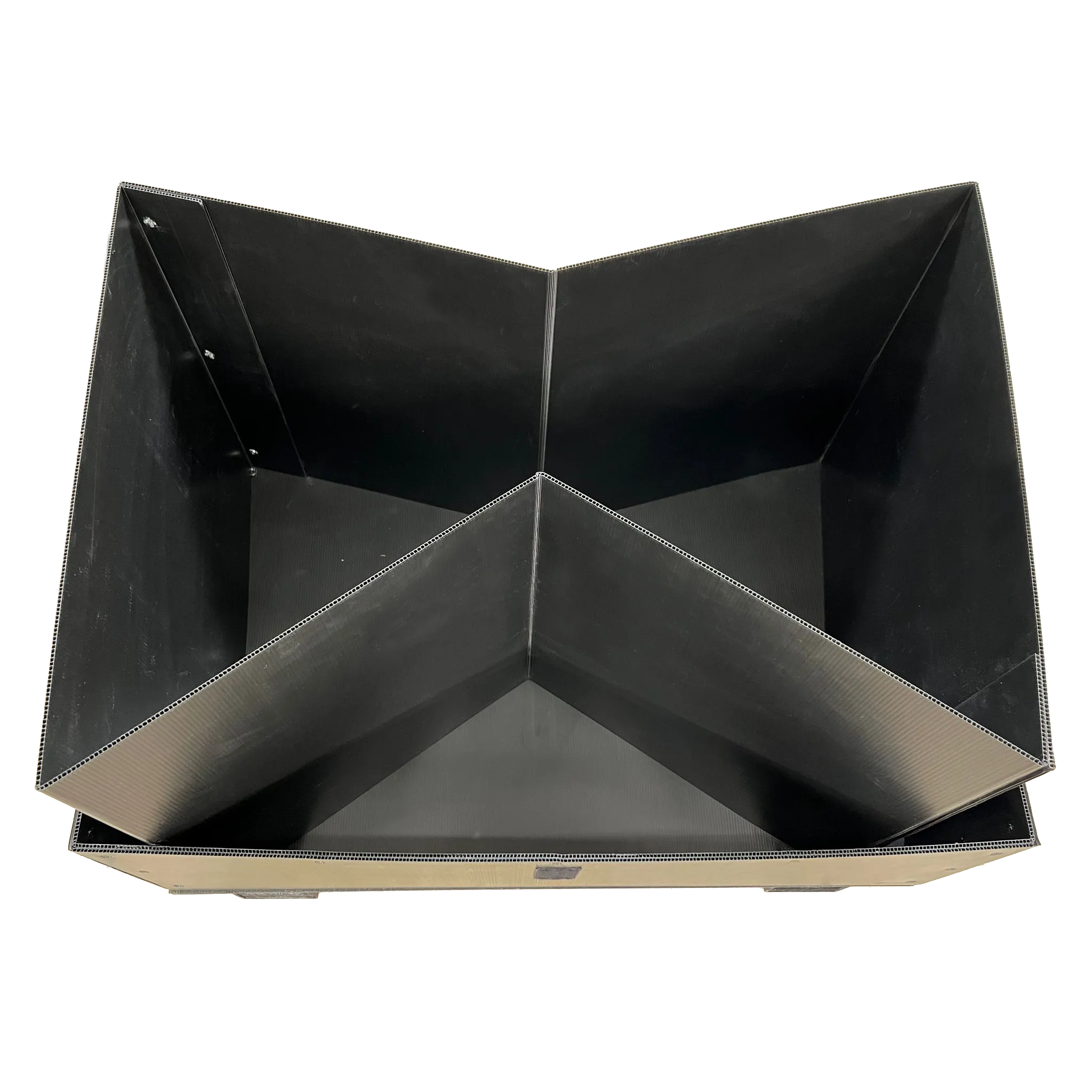

Internal dividers to separate and protect individual laptops

-

Stackable design for efficient warehouse storage

-

Vyta branding applied for a professional finish

These boxes are built to be used again and again, not flattened and forgotten.

The internal dividers were particularly important. Laptops are high value but also high risk if poorly stored. The structured compartments prevent device to device contact, reducing scratches, pressure damage and accidental impact.

The Result

What Vyta now has is not packaging. It is an operational asset.

Instead of cycling through endless cardboard cartons, they have a robust, reusable system that:

-

Reduces damage risk

-

Improves organisation

-

Speeds up handling

-

Cuts long term packaging spend

-

Supports sustainability goals

Stacked high, uniform and secure, these boxes bring order to what could otherwise be a chaotic flow of devices.

For businesses managing large volumes of IT equipment, the right box is not just a container. It is control. It is protection. It is long term cost efficiency disguised as a simple black box.

Custom Laptop Transport Cases for Streampoint

Custom Laptop Transport Cases for Streampoint

When your business depends on technology performing flawlessly on site, how that equipment is transported matters just as much as the kit itself.

We recently partnered with Streampoint, a specialist live-streaming company, to design and manufacture custom reusable transport cases for their laptop and power supply setups. The brief was simple in theory but precise in execution: maximum protection, fast setup on site and a solution built for repeated real-world use.

The challenge

Streampoint regularly transports multiple laptops and accessories to events, venues and broadcast locations. Off-the-shelf cases weren’t cutting it. Equipment needed to be:

-

Properly separated and protected

-

Quick to pack and unpack on site

-

Robust enough for frequent transport

-

Reusable and consistent across teams

The solution

We designed bespoke reusable cases with precision-cut foam inserts, tailored exactly to Streampoint’s equipment mix:

-

One case holding up to 10 × 13″ laptops

-

A second case designed for 2 × 15″ laptops

-

Dedicated compartments for power supplies and accessories

Each insert was cut to hold the laptops snugly, preventing movement during transport and keeping everything organised. No tangled cables. No stacked devices. No guesswork on site.

Built for repeated use

These aren’t single-trip boxes. The cases are designed for long-term, repeated use, offering:

-

High-impact protection for valuable IT equipment

-

Faster setup and pack-down at events

-

A more professional, organised appearance on site

-

Reduced reliance on disposable packaging

For companies like Streampoint, where equipment is constantly on the move, reusable packaging quickly becomes a productivity tool, not just a container.

Why custom matters

Every tech setup is different. Laptop sizes, quantities, power supplies and workflows vary from team to team. Custom foam inserts ensure:

-

Every item has a defined place

-

Equipment is protected exactly where it needs to be

-

Packing becomes quicker and repeatable

-

Nothing is forgotten or left behind

The result

Streampoint now has a transport solution that matches the professionalism of the service they deliver. Their laptops arrive protected, organised and ready to perform, job after job.

If you’re transporting IT equipment, AV gear or technical hardware, we can design custom reusable cases and foam inserts to suit your exact setup, whether that’s laptops, servers, cameras or control equipment.

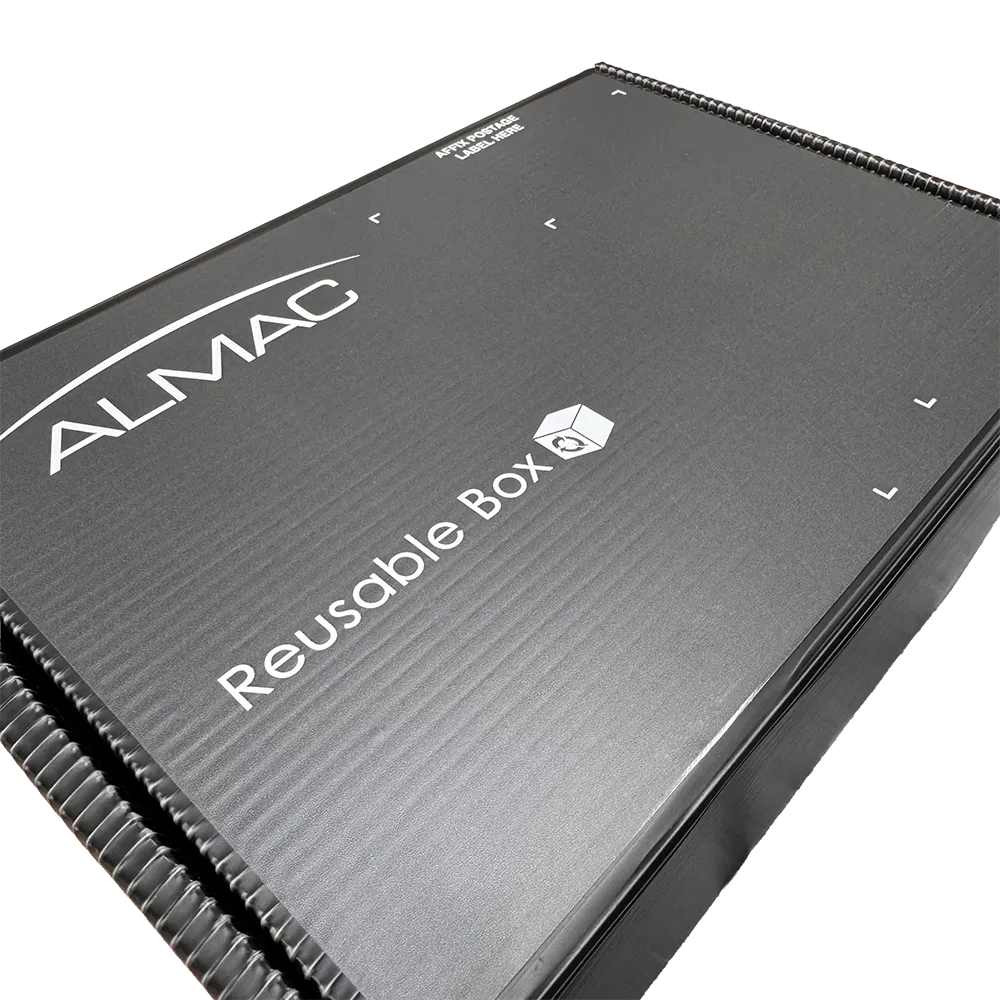

Building Three Custom Reusable Boxes for Almac Pharma

Flexible. Secure. Built for daily movement across a busy pharmaceutical environment.

When Almac Pharmaceuticals approached us, the brief was intentionally loose. They had already used a previous version of our reusable box on site and loved how robust and reliable it was for day to day movement. This time they wanted something more versatile. Instead of one box for one job, they wanted a small family of reusable boxes that could support a wide range of internal transfers across departments, buildings and specialised work areas.

So we designed three different sized boxes with matching foam cushioned inserts for general purpose use throughout their facility.

A Modular Set for Every Task

Pharmaceutical workflows never stand still. Instruments move between labs, testing areas, offices, cleanrooms and storage locations all day long. While the items can change, the demands stay the same: protect the contents, keep everything traceable and make transfers as efficient as possible.

Our solution was to create:

-

A small case for compact instruments, handheld devices and delicate items

-

A medium case for mid sized equipment and testing components

-

A large case built to handle bulkier or multi part items without compromising protection or weight

Each size follows the same structural design so staff can immediately recognise and use them in any department.

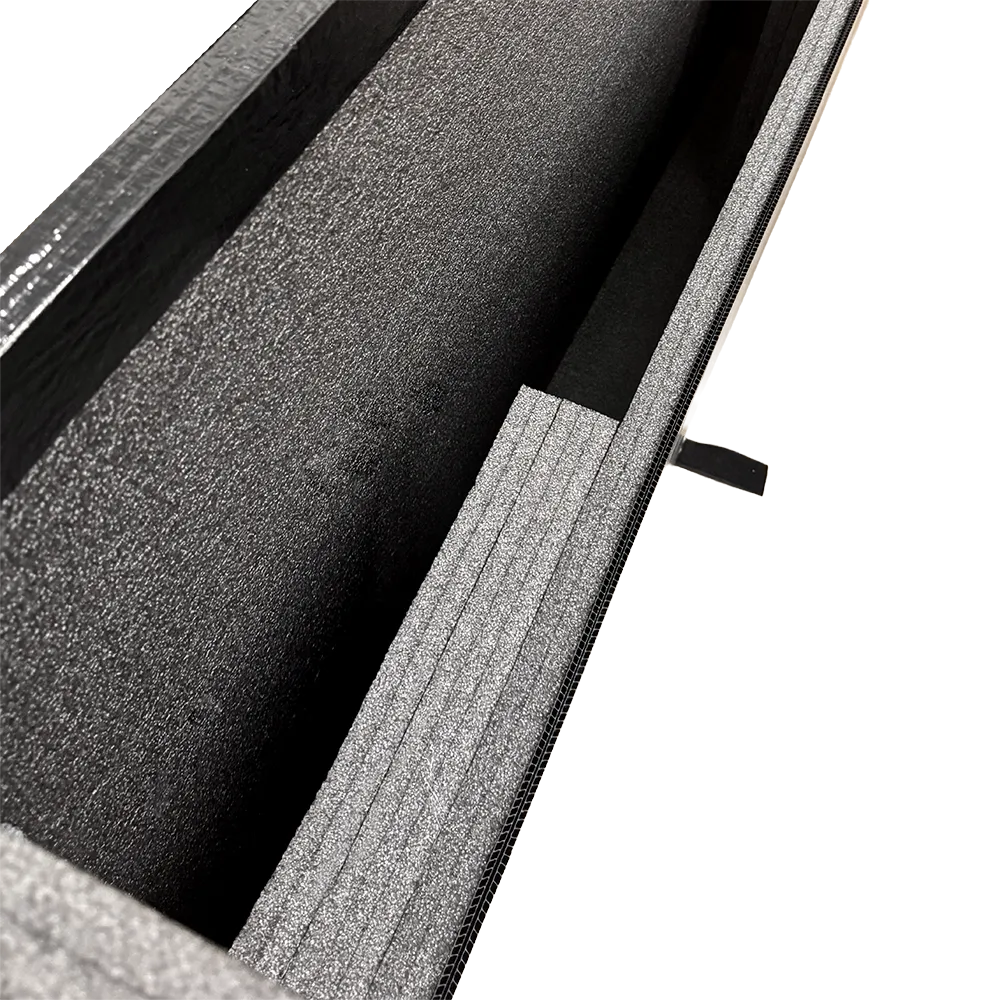

Foam Cushioned Inserts for a Flexible Payload

Because Almac needed these boxes for general purpose use, the inserts had to work for many different instruments. Instead of fixed cut outs, we engineered a foam system that gives protection without limiting the shape or size of the payload.

Our 30kg/m³ foam in flexible thicknesses creates a cushioned environment that keeps sensitive items safe during hand carry transfers or trolley movement between buildings.

Security Built Into the Design

Moving instruments inside a busy pharmaceutical environment means security and chain of custody is crucial. Each box includes dedicated locking points for cable ties, allowing staff to seal units quickly and clearly before transfer.

Once the box reaches its destination, the receiving team can confirm that the tie is intact, remove it and continue their workflow with confidence.

Durable and Reusable Across Facilities

All three boxes are built using our heavy duty corrugated polypropylene. It is lightweight, robust and totally water resistant so it stands up to the exact kind of internal transfers pharmaceutical teams carry out every day. From lab corridors to external walkways between buildings, these boxes are designed to last year after year.

A Simple Brief Turned Into a Complete Multi Box Solution

Almac gave us the freedom to design something practical and universal, and the result is a family of reusable boxes that slot seamlessly into their day to day processes. Whether the task is small, medium or large, they now have a consistent protective system that boosts efficiency and safety across their site.

If your organisation needs a similar internal movement solution or a customised version for a specialist workflow, Reusable Box can design it from the ground up.

'The Impossible Box’

Building the ‘Impossible’ Reusable Box for GSE’s 75 Inch Screens

When GSE in America approached us with a challenge to build a reusable box that could safely transport two 75 inch rental screens, we knew straight away this was no ordinary build. These are huge displays with huge value riding on them. They also needed a solution that was lightweight, strong, shock absorbent, and reusable across multiple hire cycles. A flight case wasn’t suitable and a wooden crate wasn’t practical. What they needed felt like the impossible dream

a reusable box big enough, strong enough, and smart enough to do the job.

So we built it.

To give a sense of scale we even placed a standard 24 inch monitor at the front when we took the photos. It looks like a toy. That is how big this project really is.

From Impossible to Engineered Reality

The first obstacle was size. A single 75 inch screen is large enough. Two screens packed together in one reusable system pushed the design to the edge of what corrugated polypropylene construction can handle. The structure had to remain rigid and square even when empty and still be manageable for the rental teams lifting and loading it.

The second challenge was protection. GSE ship high value screens constantly across events and installations. Their kit gets moved by crews under serious time pressure. The box had to survive being pushed

pulled

slid

manhandled

and still protect the contents.

That meant a multi zone foam layout with a floating centre divide, pressure rated sidewalls, a dual depth foam base, and enough shock absorption to cope with hard landings without adding unnecessary bulk.

Designing the Internal Foam System

Inside the box is where the real engineering sits. The foam system is built from multiple layers of 30 kg foam, all precision cut to form a tight structural cradle. There are three key parts:

-

The centre divide that keeps both screens separated and locked in place

-

Sidewall blocks that take lateral impact

-

Base supports that distribute weight evenly

-

Top compression layer that closes the internal system and prevents movement during shipment

Every piece is removable, replaceable, and designed for the realities of rental life.

This is a box that gets used

not admired on a shelf.

Strength Without Weight

We used heavy duty black 10 mm polypropylene for the outer structure, reinforced with both mechanical fixings and internal returns. When you walk around it you realise this isn’t a typical reusable box. It behaves closer to a fully engineered crate while staying lightweight enough for two people to handle.

The side handles, reinforced corners, and pull tabs mean that even though it’s huge, it stays practical in the field.

A Giant in the Workshop

When the prototype stood up in the workshop for the first time it genuinely felt monumental. Everyone who walked past stopped. It is rare for a packaging project to become a talking point

but this one did.

That is why we deliberately photographed it beside a standard 24 inch monitor. It helps people understand the scale of what we were building. You don’t often see a reusable box that towers over desks.

Why GSE Chose Reusable Box

GSE needed:

-

A long lasting solution

-

Better protection than wood or flight cases

-

Weight savings for easier handling

-

Something that could be repaired or re foamed over time

-

A box that could be shipped repeatedly without fail

We delivered all of that while keeping it fully recyclable at end of life.

The Outcome

The final product represents everything reusable packaging should be. Purpose built. Over engineered where it matters. Lightweight where possible. Repairable. Sustainable. And capable of doing what most people would say is impossible.

That’s the part we’re proud of.

This wasn’t just another job

this was solving a problem that no standard case or crate could solve. A reusable box for two monster sized screens that will now travel coast to coast across America with GSE’s rental fleet.

And it all started as the impossible dream.

Precision Packaging for Utility Body Cameras

Reusable Box Delivers Custom Packaging for Utility’s EOS Body Camera System

We recently worked with Utility, an American technology company known for their EOS body camera systems, to produce a bespoke packaging solution tailored for their latest product rollout.

Premium Presentation Meets Practical Protection

Utility needed a packaging design that could safely transport precision-built electronics while reflecting the innovation and professionalism of the EOS brand.

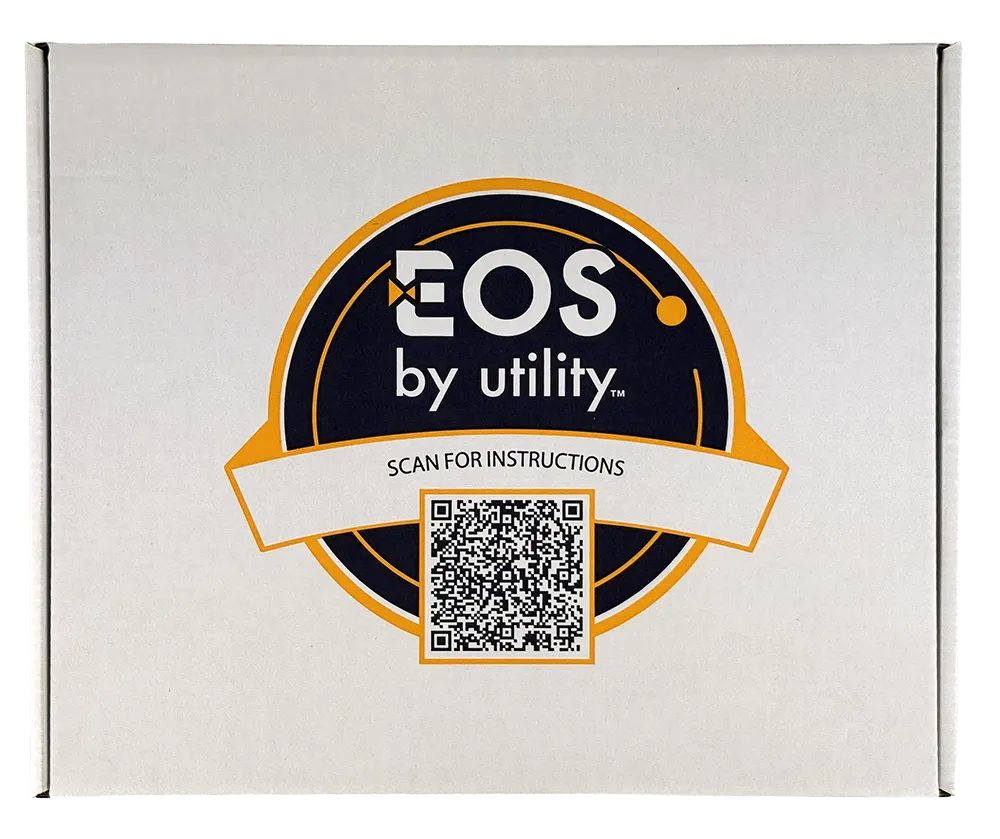

Our team at Reusable Box developed a durable white postal-style carton, digitally printed with the EOS branding in their signature navy and amber colour palette.

The lid features a bold circular logo and a scannable QR code, linking directly to setup and training resources — a perfect example of how smart packaging can enhance the end-user experience.

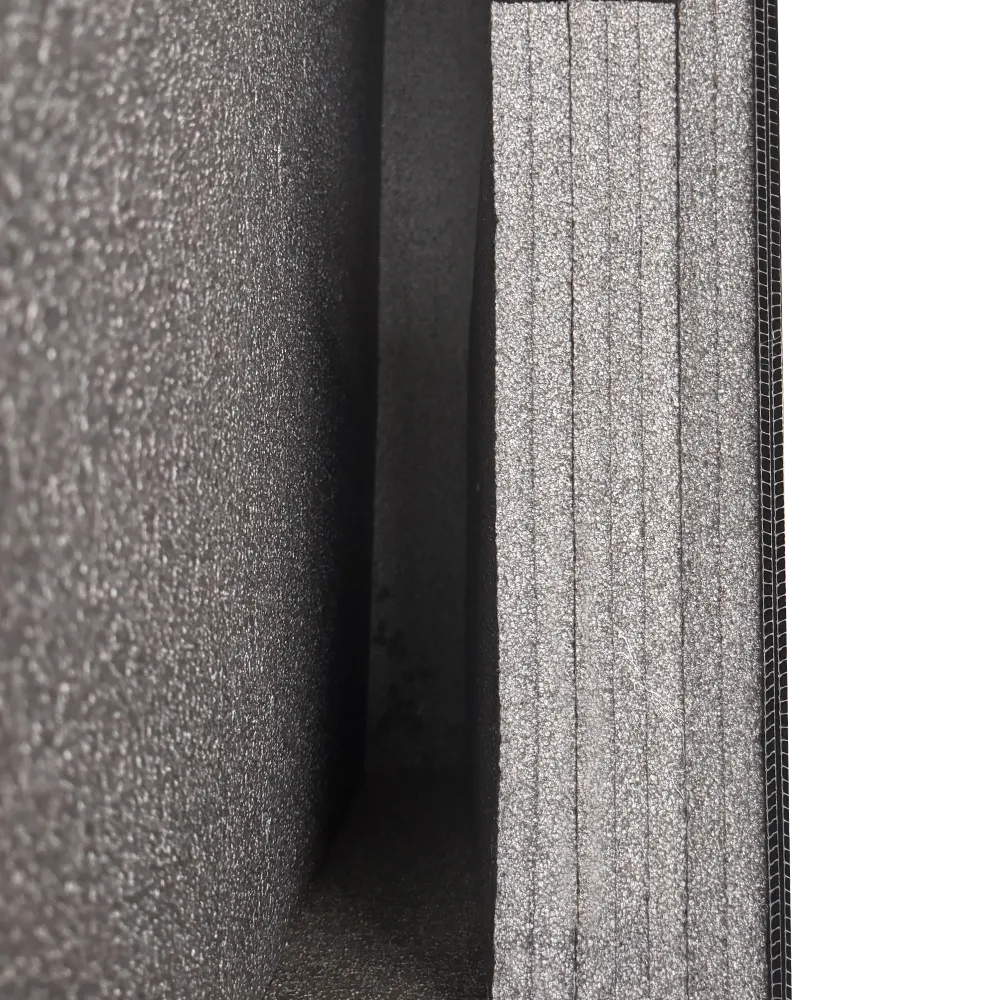

Precision-Cut Foam Interior

Inside the box, a custom foam insert was engineered to hold the EOS camera and accessories securely in place. The high-density foam was CNC-cut in-house to exact component dimensions, ensuring maximum protection during transit and a professional, organised presentation upon opening.

Reusable, Reliable, and Ready to Scale

True to our ethos, this packaging solution is recyclable, reusable, and scalable — ready for batch production and international shipment. The modular foam layout can be easily adapted for future product configurations or accessory kits, keeping the system flexible as Utility’s EOS range evolves.

Built Locally, Used Globally

From prototype to production, every stage of this project was completed in-house by the Reusable Box team in Northern Ireland — combining local craftsmanship with global standards of precision and quality.

This project demonstrates how sustainable, well-engineered packaging can support the world’s most advanced technology brands — protecting what matters, and presenting it beautifully.

Client: Utility (USA)

Product: EOS Body Camera System

Project Type: Custom Printed Postal Box with Precision Foam Insert

Sector: Law Enforcement/Military

Produced by: Reusable Box

Northern Ireland Manufacturing & Supply Chain Expo

We’re Showcasing at the Northern Ireland Manufacturing & Supply Chain Expo

We’re delighted to announce that Reusable Box will be exhibiting at the Northern Ireland Manufacturing & Supply Chain Expo, taking place at the Eikon Exhibition Centre, Lisburn on 11th September 2025.

This annual event brings together leading manufacturers, suppliers, innovators, and industry professionals from across Northern Ireland and beyond. It’s a fantastic opportunity to explore new technologies, share knowledge, and see first-hand how companies are shaping the future of manufacturing.

Why We’re Attending

At Reusable Box, we’re passionate about helping organisations reduce waste, cut costs, and improve efficiency through reusable packaging solutions. Traditional packaging often means single-use materials, wasted resources, and higher long-term costs. Our goal is to change that.

At the Expo, we’ll be showcasing:

-

Reusable tote boxes – durable, stackable, and versatile for a wide range of industries.

-

Custom protective cases – with precision-cut foam inserts for delicate or high-value items.

-

Collapsible and branded packaging – designed for efficiency, presentation, and sustainability.

What You’ll See at Our Stand

Visitors will get the chance to see our packaging solutions up close, test their durability, and discuss how we can tailor designs to fit your specific needs. From medical and scientific industries to warehousing, logistics, and retail, we create packaging that is built to last and built around you.

Join Us in Lisburn

If you’re attending the Expo, we’d love to meet you. Stop by our stand, chat with the team, and see how reusable packaging can transform your operations.

📍 Northern Ireland Manufacturing & Supply Chain Expo

📅 11th September 2025

📌 Eikon Exhibition Centre, Lisburn

👉 Find out more and register here: Northern Ireland Manufacturing & Supply Chain Expo

We look forward to connecting with industry leaders, partners, and new faces as we continue our mission to make packaging smarter, greener, and more efficient.

New Tech, Sharper Results

New Tech, Sharper Results: Introducing Our DYSS X7 Digital Cutter

At Reusable Box, we’re always looking for ways to push quality, speed, and sustainability forward. That’s why we’ve just added the DYSS X7 Digital Cutting System to our workshop — and it’s a game-changer for custom packaging.

Whether we’re building precision transport boxes for medical equipment or developing collapsible solutions for high-end scale models, our new cutting machine means even more accuracy, flexibility, and efficiency for our clients.

What Is the DYSS X7?

The DYSS X7 is a versatile digital cutting system, designed to process a wide variety of materials with razor-sharp accuracy — from corrugated plastic and foam inserts to cardboard, vinyl, and beyond.

It uses advanced routing, kiss-cutting, and creasing tools, allowing us to create complex parts, internal foam layouts, and folding designs faster and cleaner than ever before.

Why It Matters to Our Clients

Here’s how this upgrade benefits the businesses we serve:

-

Faster Turnarounds – Quicker setup and production mean we can meet tighter deadlines

-

Unmatched Precision – Every cut, every slot, every panel edge is clean and perfectly aligned

-

Material Efficiency – Less waste, better yield, and smarter layout planning

-

Prototyping Made Easy – We can now quickly mock up sample designs before full production

-

Complex Inserts? No Problem. – Intricate foam layouts for delicate items like instruments, electronics or collector items are now easier to produce at scale

Stronger Capability, Same Custom Focus

This machine strengthens what we already do best: bespoke, sustainable, reusable packaging.

From one-off custom builds to full repeatable runs, the DYSS X7 allows us to stay lean, flexible, and fiercely quality-driven — whether we’re producing 5 boxes or 500.

📦 Have a tricky product to ship or store?

We’re now better equipped than ever to design your perfect solution.

📩 Get in touch and let’s build something clever.

Smart Shipping for High-End Scale Models

Precision Meets Sustainability: A Collapsible Transport Box for High-End Scale Models

When a manufacturer of high-end scale models approached Reusable Box, they brought a unique packaging challenge:

How do you safely ship a luxury-scale model worth thousands of pounds while staying aligned with sustainability goals — and keeping return logistics affordable?

The answer: a fully collapsible, reusable transport box engineered for both protection and practicality.

The Challenge

This client produces extremely detailed, handcrafted replicas, with each model priced in the five-figure range.

Every item is a collector’s piece — fragile, valuable, and irreplaceable.

They needed packaging that could:

-

Guarantee safe delivery to international customers

-

Reflect their brand’s sustainability focus

-

Be returned cost-effectively for reuse

Our Solution

We developed a custom transport box using robust corrugated plastic panels with laser-cut internal foam inserts, tailored to the shape of each model.

To solve the return issue, we engineered the box to be collapsible after use.

Once the model is removed, the recipient can easily fold the box down, reducing its size by over 60%.

The return trip becomes lighter, smaller, and cheaper — while the box lives on for multiple deliveries.

Key features include:

-

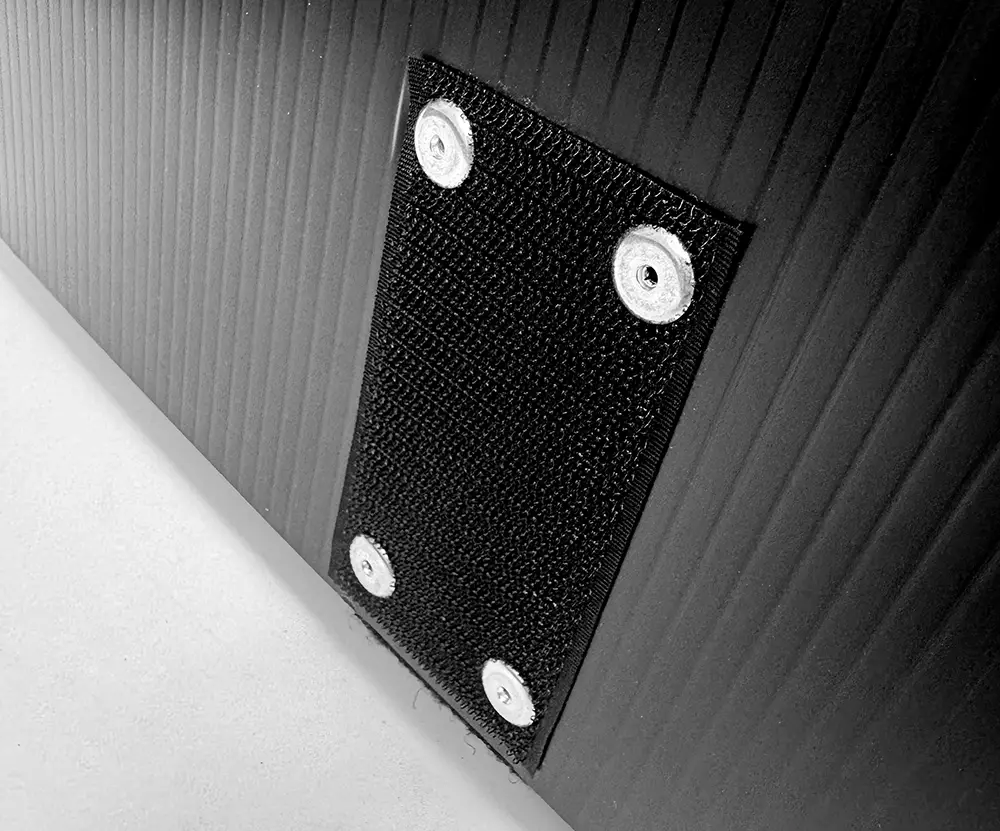

Printed fold-down instructions inside the lid

-

Secure Velcro straps and locking tabs

-

Lightweight, rigid construction that protects on outbound and return legs

The Result

✅ Safe, damage-free global shipping of high-value models

✅ Dramatic reduction in return shipping costs

✅ A durable, reusable system aligned with eco-conscious branding

This project is a perfect example of how thoughtful design can balance logistics, sustainability, and customer experience — all in one smart package.

Need a smarter way to ship high-value items?

📩 Get in touch — we’ll build your perfect box.

Proud to Join 'Made in Britain'

Proud to Join Made in Britain: Championing Sustainable, UK-Made Warehouse Solutions

At Reusable Box, we’re proud to announce that we are now officially registered with Made in Britain — the recognised mark of British manufacturing excellence.

This membership is more than just a badge. It’s a reflection of our commitment to quality, sustainability, and local industry. Every reusable storage solution we supply is designed and distributed from within the UK, ensuring shorter supply chains, faster lead times, and a lower carbon footprint.

Joining Made in Britain aligns perfectly with our mission to help warehouses across the UK and beyond reduce waste, cut costs, and hit ESG targets — all while supporting British jobs and engineering.

Why it Matters:

-

✅ Locally designed & distributed solutions

-

✅ Lower transport emissions & faster fulfilment

-

✅ Supports UK jobs, industry, and innovation

-

✅ Recognised assurance for procurement teams

-

✅ Reinforces your ESG & sustainable sourcing efforts

We’re proud to stand alongside other great British manufacturers and look forward to continuing to deliver products that are built to last, built responsibly, and built in Britain.

The Hidden Cost of Single-Use Packaging in Warehouse Operations

The Hidden Cost of Single-Use Packaging in Warehouse Operations

In the fast-paced world of warehouse logistics, operational efficiency is everything. Yet many facilities continue to rely on single-use packaging — cardboard boxes, shrink wrap, and disposable totes — without realising the long-term costs they introduce.

What seems like a cheap, convenient option on the surface can silently erode warehouse budgets, waste time, and hold your business back from reaching its sustainability goals. Here’s why forward-thinking procurement professionals are rethinking their packaging strategy.

1. Repeat Costs Add Up Fast

While a single cardboard box might cost pennies, multiply that across thousands of weekly shipments, damaged returns, and supplier transfers, and you’re looking at a recurring expense that never ends.

By contrast, reusable plastic containers are an upfront investment that quickly pays off — especially for operations with high turnover or closed-loop logistics.

2. Increased Waste Handling

Every time a cardboard box is discarded, it adds to your waste management burden. Sorting, baling, and disposing of packaging waste consumes both time and money — not to mention the space it takes up on your warehouse floor.

Reusable boxes cut waste volumes drastically, freeing up both labour and square footage.

3. Reduced Load Stability and Protection

Single-use packaging often fails under stress — especially in high-volume environments. Crushed corners, split seams, and rain-damaged cardboard mean product losses, slowdowns, and rework.

Heavy-duty reusable totes provide uniform stacking, structural integrity, and better product protection, especially during transit and racking.

4. Hidden Environmental Costs

If your business is working towards ESG or net-zero targets, your packaging choices matter. The carbon footprint of repeated single-use packaging manufacture and disposal can be significant.

Using reusable containers helps reduce your operation’s environmental impact — and demonstrates your commitment to sustainable procurement.

5. Missed Efficiency Gains

Stackable reusable boxes are designed to integrate into racking systems, conveyors, and pick/pack stations. This leads to faster handling, fewer errors, and improved warehouse flow.

Sticking with single-use boxes often means missed opportunities for automation, standardisation, and layout optimisation.

👉 Explore our Warehouse Storage Solutions

👉 Or Request a Free Quote to get started today.