Why Foam Inserts Are the Unsung Hero of Reusable Packaging

When people think of reusable packaging, they often focus on the external features — the durability of the box, its stackability, or the environmental benefits. But inside every great box is an often overlooked, yet essential component: the foam insert.

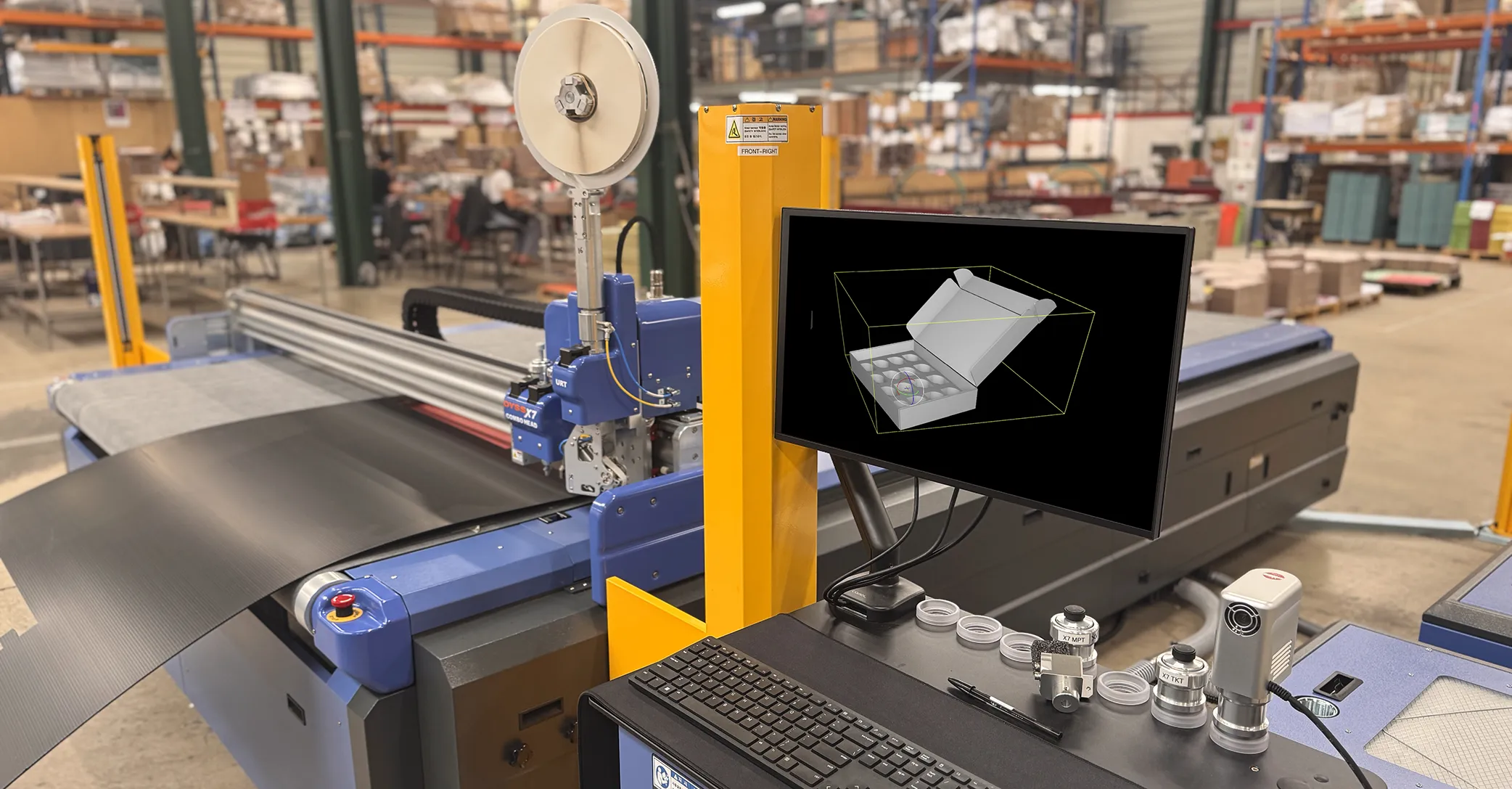

At Reusable Box, we design every insert with precision, purpose, and protection in mind.

🔍 What Are Foam Inserts and Why Do They Matter?

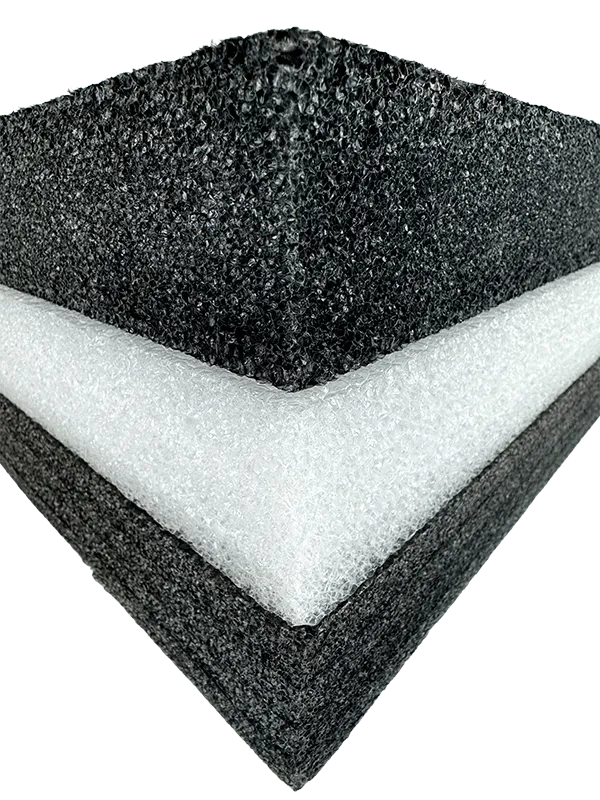

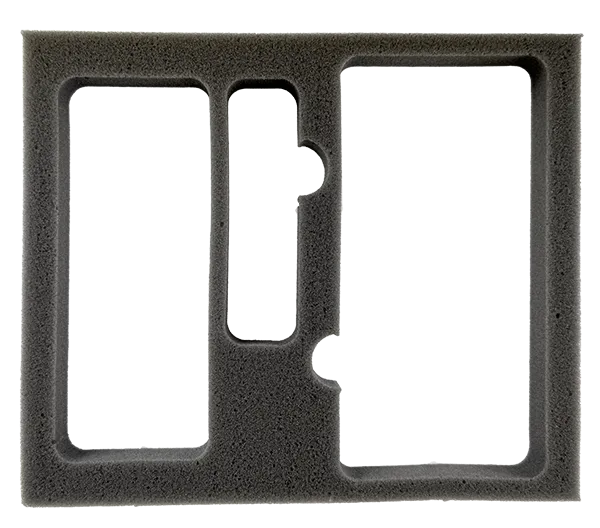

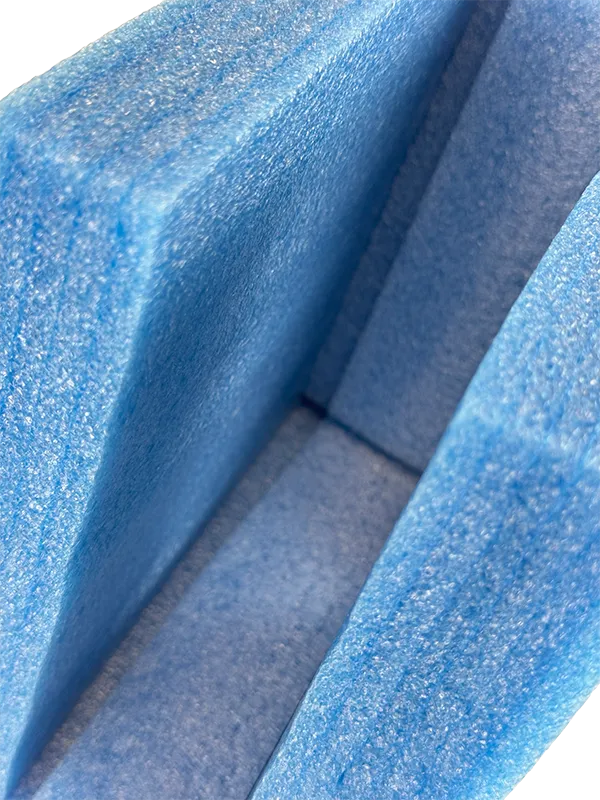

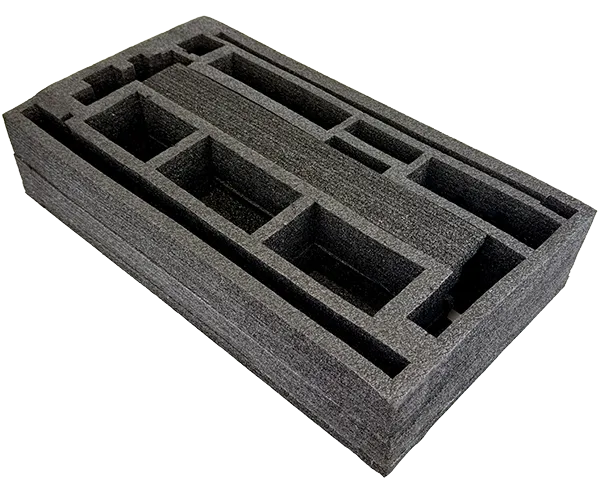

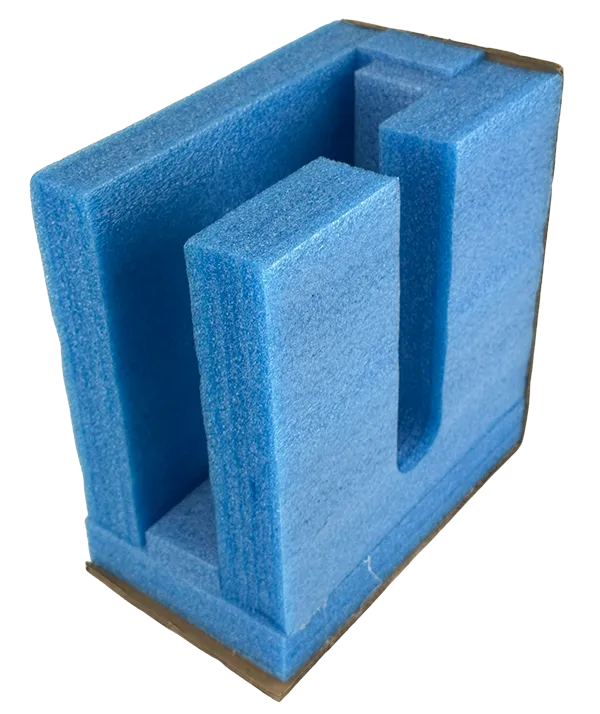

Foam inserts are custom-cut pieces of high-density foam placed inside your reusable box to house and protect your products. Think of them as tailored compartments that securely cradle each item, preventing movement, damage, and mishandling during transit.

They’re especially critical in sectors like:

-

Pharmaceutical and medical packaging (e.g. Escort Data Loggers)

-

Electronics and instrumentation

-

Military-grade or aerospace components

-

Film & TV kit transport

✅ The Reusable Box Approach to Foam Design

Every insert we create is made to match your product’s exact dimensions. That means:

-

No excess movement

-

Faster packing and unpacking

-

Reduced risk of damage

-

More consistent workflows across your supply chain

We can also design:

-

Multi-tiered inserts

-

Compartments for cables, accessories or documents

-

Colour-coded foam for visual identification

-

Water-resistant or antistatic foams, depending on application

♻️ Why Custom Foam + Reusable Box = Long-Term Gains

A well-designed foam insert extends the life of your packaging — and your product. Combined with our reusable outer boxes, the insert plays a big role in:

-

Minimising product damage

-

Reducing the need for replacement parts or reshipments

-

Lowering packaging waste

-

Creating a consistently professional appearance for your brand

🛠️ Real Example: Almac Pharmaceuticals

We recently helped Almac transport sensitive Escort Data Loggers using a custom two-tier reusable box. The top layer featured precision-cut foam inserts to secure the loggers, while the bottom layer housed their boxed units. The result? Faster, safer packing, and zero damage in transit.

📩 Ready for Your Own Insert?

If you’re shipping high-value, high-risk, or high-volume products, don’t settle for generic packaging. Let’s design something that protects what matters most.

5 Ways Reusable Storage Boxes Improve Warehouse Efficiency

5 Ways Reusable Storage Boxes Improve Warehouse Efficiency

In today’s fast-moving logistics and fulfilment environments, every minute and every metre of warehouse space counts. While many businesses focus on optimising software, labour, and racking systems, one often-overlooked element is the packaging itself.

Reusable storage boxes don’t just reduce waste — they actively improve warehouse efficiency in ways that benefit operations, procurement, and the bottom line.

Here’s how:

1. 🧱 Stackable Design Saves Space

Reusable boxes are designed for uniform stacking, helping you make full use of vertical space on pallets, in racking, and during transit. This increases storage density and reduces wasted floor area — a key win for space-constrained operations.

2. ⏱ Faster Picking and Packing

Standardised container sizes mean fewer adjustments, less fumbling, and smoother workflows for warehouse operatives. Totes fit predictably into pick faces, conveyor systems, and order prep zones — helping staff work faster and more accurately.

3. 🚚 Reduced Product Damage in Transit

Strong, rigid containers provide better protection than single-use packaging. That means fewer damaged goods, fewer returns, and less time spent on repacking or managing claims — all of which slows down warehouse flow.

4. 🔄 Simplified Returns and Reuse Cycles

In closed-loop or supplier-return systems, reusable boxes can be easily sanitised, relabelled, and redeployed — no need to reorder packaging or break down waste. This helps improve turnaround times and reduce admin overhead.

5. ♻️ Supports Automation and Lean Operations

With their consistent shape and structural strength, reusable containers are ideal for use with automated picking systems, vertical lifts, or robotic conveyors. They also enable lean warehouse layouts by reducing clutter and packaging variability.

Ready to Improve Efficiency?

If your warehouse is still relying on throwaway packaging, you’re missing a simple opportunity to streamline operations.

At Reusable Box, we help procurement teams and warehouse managers across the UK and USA make the shift to smarter, longer-lasting storage solutions.

👉 Explore our Warehouse Storage Range

👉 Get in Touch for a Quote

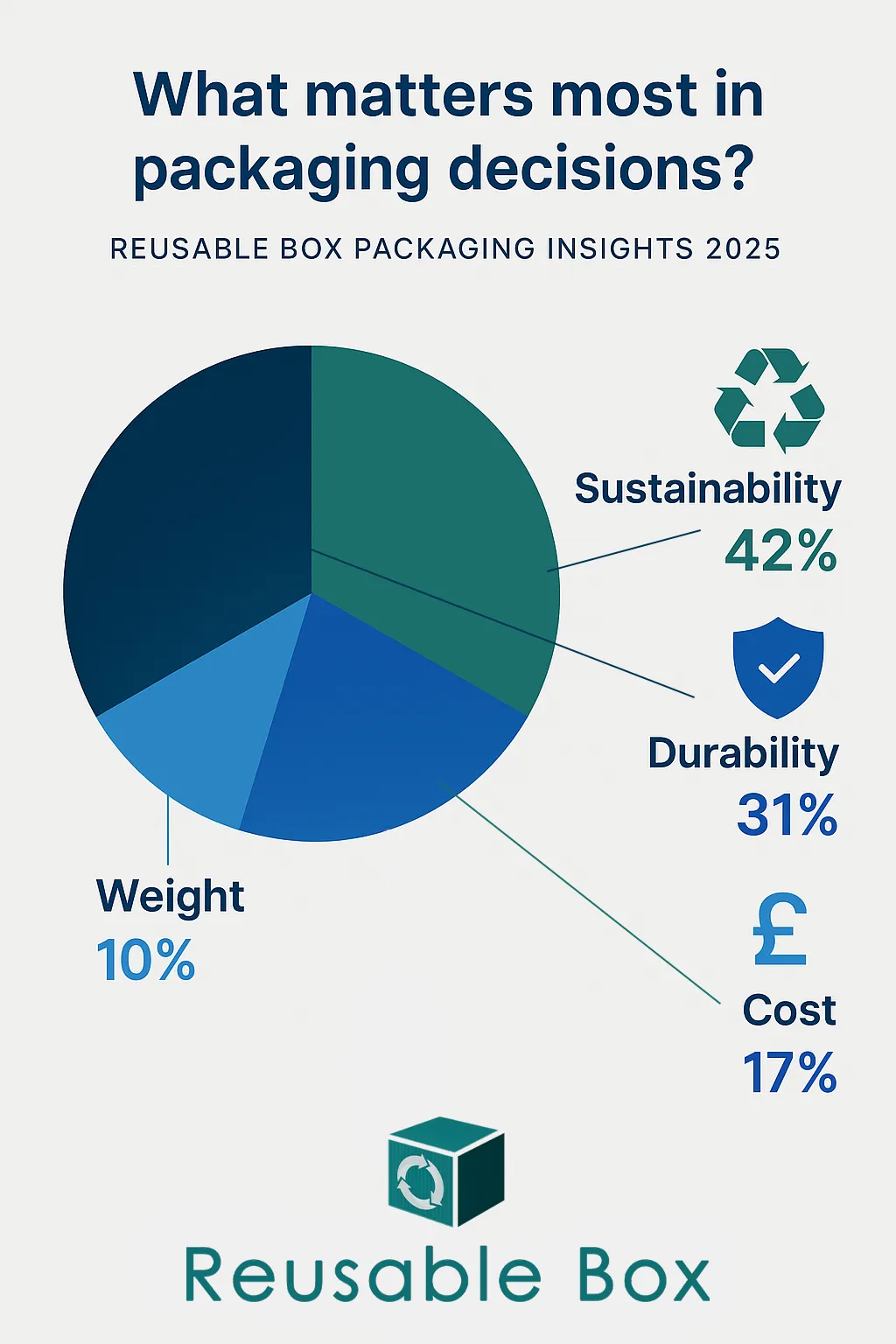

What Really Matters in Packaging Decisions? Our 2025 Research Reveals the Top Priorities

At Reusable Box, we don’t just make packaging — we solve packaging problems. To better understand what matters most to our clients and the wider market, we recently conducted a large-scale insights campaign targeting procurement managers, logistics coordinators, and packaging decision-makers across multiple industries.

From healthcare and aerospace to electronics, events, and film production, one thing became clear: businesses are evolving their packaging priorities.

So, what’s at the top of the list in 2025?

📊 The Results Are In:

Here’s how our respondents ranked the most important factors in their packaging decisions:

-

♻️ Sustainability – 42%

-

🛡️ Durability – 31%

-

💷 Cost – 17%

-

⚖️ Weight – 10%

♻️ Sustainability Takes the Lead (42%)

No surprise here. With growing ESG commitments, green supply chain goals, and rising pressure from stakeholders, sustainability has taken the top spot.

Reusable packaging offers a powerful solution:

-

Fewer single-use materials

-

Less waste generated over time

-

Longer product lifecycle

-

Fully recyclable internal components (e.g. foam inserts)

It’s clear that businesses are looking beyond the first journey — they’re designing for the long haul.

🛡️ Durability Comes in Second (31%)

Durability matters more than ever in industries with complex handling processes. From rugged transport environments to long-term storage, packaging that protects — and keeps protecting — is essential.

That’s why Reusable Box focuses on:

-

Sturdy box construction using heavy-duty materials

-

Impact-resistant foam inserts

-

Lockable lids and stackable designs

When packaging gets reused hundreds of times without failing, it becomes more than packaging — it becomes part of your workflow.

💷 Cost Still Matters (17%)

While not the top concern, cost is always part of the equation — especially in high-volume operations. But many respondents acknowledged that long-term savings are more valuable than initial cost cuts.

Reusable Box offers ROI-friendly solutions by:

-

Reducing the need for repurchasing

-

Lowering product damage and returns

-

Streamlining loading and transport times

-

Supporting tax and compliance goals related to waste reduction

⚖️ Weight Is a Factor, But Not a Deal-Breaker (10%)

Weight matters most in air freight or manual handling operations. Lighter solutions are sometimes preferable, but many customers told us they’d happily accept added weight for more durability and environmental gain.

That’s why we work to strike the balance: keeping our boxes strong but efficient, without compromising performance.

🔍 What This Means for Your Business

If you’re still relying on single-use or flimsy packaging solutions, you’re not aligned with what the market values most. Customers, stakeholders, and your team all benefit from smarter, reusable designs.

At Reusable Box, we:

-

Tailor packaging to your product

-

Design with industry-specific demands in mind

-

Offer expert advice on reusability, sustainability and logistics

-

Manufacture right here in the UK

📞 Want Packaging That Ticks All the Boxes?

Let’s create a packaging system that protects your product, your reputation, and your planet.

👉 Talk to us now or explore our solutions at www.reusablebox.net

Case Study: Bespoke Two-Tiered Reusable Box for Almac Pharmaceuticals

Case Study: Bespoke Two-Tiered Reusable Box for Almac Pharmaceuticals

Client: Almac Pharmaceuticals

Sector: Medical & Scientific

Location: Global Operations, Headquartered in Northern Ireland

Overview

Almac Pharmaceuticals, a global leader in pharmaceutical development and manufacturing, approached ReusableBox.net with a packaging challenge. They needed a reliable, reusable solution for transporting sensitive eye drop products equipped with Escort Data Loggers, ensuring both product safety and logistical efficiency.

Challenge

Almac’s logistics team required a packaging solution that could:

-

Securely hold Escort Loggers for temperature-sensitive eye drops

-

Accommodate multiple units while maintaining order and protection

-

Allow for easy return and reuse, in line with their sustainability initiatives

-

Withstand repeated handling through global distribution networks

Standard off-the-shelf packaging was falling short, especially in maintaining product orientation and preventing movement in transit.

Our Solution

We designed and manufactured a custom two-tiered reusable box tailored to Almac’s specific product and handling needs:

Tier 1: Custom Foam Insert for Escort Loggers

-

Precision-cut high-density foam to snugly fit and protect Escort Data Loggers

-

Eye drop containers nestled individually to prevent damage or shifting

-

Easy access design for efficient loading and unloading

Tier 2: Compartment for Boxed Items

-

The second layer was engineered to hold boxed batches of the same products

-

Rigid dividers and stabilisers ensured all items remained secure during transit

-

Layered structure allowed easy separation of monitored and bulk product components

Material & Sustainability

-

Durable plastic outer shell designed for long-term reuse

-

Fully returnable packaging, reducing waste and improving carbon footprint

-

Designed for easy cleaning and sanitisation between cycles

Results

-

Improved Protection: The custom foam prevented movement, protecting sensitive equipment and maintaining calibration integrity.

-

Streamlined Handling: Two-tier design simplified the packing process and product segregation.

-

Cost Efficiency: Reusability reduced Almac’s need for single-use packaging, driving down long-term costs.

-

Sustainability Win: The returnable nature of the boxes aligned with Almac’s green initiatives and reduced packaging waste significantly.

Testimonial

“The reusable solution provided by ReusableBox.net transformed the way we package and transport this product line. It’s secure, robust, and aligns with our ongoing sustainability goals.”

— Logistics Coordinator, Almac Pharmaceuticals

5 Ways Marketing Teams Use Reusable Boxes for Campaign Logistics

Intro:

Marketing campaigns don’t just live in spreadsheets—they live in warehouses, vans, event tents, and retail displays. Behind every successful brand activation or merchandise drop is a team juggling logistics, deadlines, and assets. One tool marketing teams increasingly rely on? Reusable plastic storage boxes.

Strong, stackable, and easy to label, these boxes help streamline campaign logistics from end to end. Whether you’re packing event kits, shipping POS displays, or organising merchandise stock, here are five real-world ways reusable boxes are making life easier for marketing teams across the UK.

✅ 1. Preparing Event Kits & Sampling Packs

Whether it’s a product launch, a conference giveaway, or a field marketing activation, pre-packed kits help teams deliver consistency across locations.

Reusable boxes are ideal for:

-

Pre-loading event packs with leaflets, merchandise, and signage

-

Ensuring every box contains the same quantity of items

-

Reducing setup time by allowing team members to grab and go

-

Protecting fragile or high-value materials during transit

Reusable boxes are especially helpful for roadshows, where consistent packing and repacking is key to a seamless rollout across multiple venues.

✅ 2. POS & Display Storage

Point-of-sale materials—like plinths, signage, shelf wobblers or demo stands—often need protection and organisation between uses.

With reusable boxes, you can:

-

Prevent scuffing or bending of display boards

-

Keep all components (e.g. clamps, bases, signage) together in one box

-

Use internal dividers or foam inserts for delicate parts

-

Easily label boxes by campaign or store region

This means faster turnaround between setups and a professional presentation every time.

✅ 3. Merchandise Fulfilment Centres

Agencies and brands often run fulfilment operations from warehouses or temporary spaces. Standardised plastic boxes help improve efficiency by:

-

Stacking neatly on shelves or pallets

-

Making picking and packing easier and faster

-

Colour-coding by client, region, or campaign

-

Holding up better under frequent use than cardboard cartons

Over time, reusable boxes reduce packing waste and make your stockroom or fulfilment hub more organised and scalable.

✅ 4. On-Tour Activation Kits

When you’re taking a brand on tour—whether across campuses, shopping centres or trade shows—durability and repeatability matter.

Reusable boxes let teams:

-

Pack up once and reuse the same setup in every city

-

Fit boxes consistently in vans, trolleys or flight cases

-

Survive rain, steps, forklifts and tight loading zones

-

Repurpose the same storage for returns or leftover stock

Bonus: the uniform design helps your team look more professional and organised to clients and crowds alike.

✅ 5. Internal Office or Marketing Department Storage

Not every campaign ends with a giveaway—often you have leftover merch or re-usable display items that need storing until next time.

Use reusable boxes to:

-

Store excess branded items for future use

-

Label boxes by campaign, year, or target market

-

Protect soft goods (like t-shirts or bags) from dust and damp

-

Easily transport samples to meetings or pitch events

This turns chaotic closets into a structured marketing storeroom.

✅ Final Thoughts

From the warehouse to the roadshow, reusable plastic boxes are a behind-the-scenes hero of modern marketing. They simplify logistics, reduce damage, and keep everything campaign-ready—again and again.

The Ultimate Checklist for Packing Effective Training Kits

Introduction

A well-packed training kit is the foundation of an effective session. Whether you’re training engineers, warehouse staff, or new hires, your materials need to arrive organised, intact, and ready to use.

Here’s a simple checklist to ensure your kits are always training-ready — and how reusable boxes help.

✅ 1. Choose Consistent Box Sizes

Using uniform box sizes simplifies packing, stacking, and transport. Reusable boxes give you that consistency every time.

✅ 2. Use Protective Inserts

Foam inserts or dividers help protect sensitive equipment like meters, laptops, or demonstration tools.

✅ 3. Label Clearly

Whether it’s “Module 1,” “First Aid Kit,” or “Electrical Training,” clear external labels help speed up session setup.

✅ 4. Standardise Contents

Reusable boxes make it easy to pre-pack identical kits for multiple sessions — no need to start from scratch each time.

✅ 5. Track Your Kits

With barcode or RFID tags on your boxes, you’ll always know where your materials are and when they were last used.

Conclusion

Reusable boxes aren’t just for transport — they’re part of your training system. With the right prep and packaging, you’ll deliver smoother, more professional sessions every time.

How to Store and Transport Promotional Merchandise Without Damage

Promotional merchandise is often the first physical touchpoint between your brand and your audience—so presentation matters. Whether it’s branded pens, mugs, brochures, tote bags, or pop-up displays, these items need to arrive clean, organised, and damage-free at events, retail locations, or client offices.

Yet all too often, businesses rely on flimsy cardboard boxes, plastic wrap, or improvised storage that simply can’t stand up to the rigours of logistics. Crushed corners, moisture damage, missing items—it’s a recipe for wasted budget and poor impressions.

In this article, we explore why reusable plastic storage boxes are the smart choice for storing and transporting promotional merchandise safely—and how they help marketers and logistics teams streamline every campaign.

✅ 1. Common Damage Risks in Promo Logistics

Promotional items go through a surprising amount of handling—from fulfilment warehouses to delivery vans, venues, and back again. The typical risks include:

-

Crushing: Lightweight packaging often can’t handle the weight of other boxes stacked on top.

-

Moisture Exposure: Cardboard offers little protection against rain, spills, or condensation in vans or event venues.

-

Impact Damage: Loose packing or movement in transit can crack mugs, scuff boxes, or tear soft items.

-

Item Loss or Misplacement: Without secure closures or compartments, small items can go missing—especially during busy event setups.

-

Presentation Issues: When packaging is torn or sloppy, the perceived value of your merchandise drops—even if the item is intact.

These issues not only result in product loss, but they can also damage brand image during high-stakes campaigns or launches.

✅ 2. Reusable Boxes vs. Cardboard: A Practical Comparison

Reusable plastic boxes offer durability, uniformity, and protection that traditional packaging simply can’t match:

| Feature | Cardboard Boxes | Reusable Plastic Boxes |

|---|---|---|

| Durability | Low – easily crushed or torn | High – impact-resistant and stackable |

| Moisture Resistance | Very low | Fully water-resistant |

| Stacking Strength | Limited – risk of collapsing | Engineered for stable stacking |

| Reusability | One-time use | Long-term use, over 100 cycles |

| Sustainability | Disposable waste | Recyclable and reusable |

Switching to plastic boxes can reduce breakages and speed up packing, all while cutting down on packaging waste.

✅ 3. Use Labels, Colour Coding & Branding for Organisation

Organisation is critical when handling multiple items across multiple destinations. Reusable boxes make this easier with options for:

-

Custom Labels: Add adhesive or reusable inserts for box contents or destinations.

-

Colour Coding: Assign different box colours for event types, product categories, or regions.

-

Temporary Branding: Use vinyl wraps or branded inserts to make boxes client-facing for events or demos.

This visual organisation reduces errors, improves load-out times, and ensures team members always know what’s inside.

✅ 4. Improve Event Setup & Breakdown with Consistent Box Sizes

Event logistics often involve tight schedules, shared storage spaces, and limited loading time. Reusable boxes provide a consistent, modular solution that allows for:

-

Quick stacking and staging: Uniform sizes simplify van loading and venue setup.

-

Faster unpacking: Pre-packed boxes arrive ready for display with no repacking needed.

-

Easy breakdown: Staff can quickly reload merchandise in the same boxes for return logistics.

-

Protective return storage: Safely bring leftover stock or reusable items back without damage.

Marketing teams running pop-ups, exhibitions, or roadshows benefit from boxes that are tough, transportable, and reusable again and again.

✅ 5. Reusable = Smarter Spend Over Time

While cardboard might seem cheaper upfront, the long-term cost of breakages, replacements, and repacking quickly adds up. Reusable boxes offer:

-

Lower total cost of ownership

-

Fewer packaging purchases

-

Better protection = less product loss

-

Improved professional presentation

For agencies, this also means a more premium experience for clients and greater control over logistics without constantly sourcing packaging.

✅ Final Thoughts

Promotional campaigns are all about delivering impact—but that starts with delivering your merchandise intact and on time. Reusable plastic boxes give you the durability, organisation, and professional appearance your brand deserves.

Whether you’re running a roadshow, packing event kits, or shipping branded materials to partners, it pays to think inside the box—a reusable one.

Essential Storage Tips for Film Production Crews On the Move

Whether you’re on a fast-paced location shoot or managing back-to-back studio days, how you store and transport your gear makes a big difference. Poorly organised equipment slows down production, risks breakage, and costs valuable time.

In this post, we’ll share practical storage and transport tips used by professional film crews to keep operations smooth, efficient, and damage-free.

Key Sections:

1. Categorise & Label Everything

Use clearly marked reusable boxes for cameras, sound, lighting, and props. Colour-coded labels or printed inserts can save hours on set.

2. Invest in Stackable, Durable Containers

Flimsy crates won’t survive multiple load-ins. Choose industrial-grade boxes that protect gear from impacts, spills, and weather changes.

3. Keep Gear Modular for Fast Turnaround

Create “grab kits” for common tasks—pre-packed boxes with tools, cables, or accessories ready to go.

4. Plan for Transit & Load-Ins

Wheeled trolleys and uniform box sizes simplify van packing and venue access. Boxes should stack securely and be easy to unload quickly.

5. Reduce Waste with Reusables

Replacing cardboard and single-use wrapping with robust reusable boxes saves money and reduces clutter on set.

Sustainable Training Logistics: How Reusable Boxes Cut Waste and Cost

Introduction

Training teams often cycle through huge amounts of disposable packaging — cardboard boxes, bubble wrap, tape. It adds up quickly, both in waste and cost. If your organisation is looking to train smarter and greener, reusable packaging is a powerful step forward.

The Hidden Waste in Training Operations

Every time a session is packed with throwaway materials, you’re increasing environmental impact — and likely your budget. Single-use packaging also leads to inconsistent presentation and unreliable protection.

Reusable Boxes: The Greener, Smarter Option

-

♻️ Fewer materials in landfill

-

💰 Lower long-term costs

-

📦 More professional appearance

-

🔁 Repeatable kits with less effort

Perfect for ESG & Sustainability Goals

As more organisations adopt Environmental, Social, and Governance (ESG) policies, reusable packaging becomes an easy win. It supports responsible procurement while improving operational efficiency.

Conclusion

Switching to reusable boxes for your training operations isn’t just eco-friendly — it’s operationally smart. Whether you’re rolling out training to 5 people or 500, you’ll save money, reduce waste, and raise your training game.

How to Choose the Right Reusable Box for Your Business

Making the right decision for your business

Switching to reusable packaging is a smart step, but it’s important to choose the right solution for your needs. Here’s what to consider when selecting a reusable box that works for your business.

1. Define Your Use Case

Start with how and where your box will be used. Is it for shipping, storage, display, or internal transfers? Each use may demand different durability, sizes, or features.

2. Consider Size and Load Capacity

Think about what you’re packing. A snug fit reduces movement and potential damage. We offer standard sizes and fully bespoke options.

3. Customise for Brand and Function

Add logos, colours, or messaging to make the box your own. Functionally, you might need stackable designs, handles, or locking lids.

4. Material Matters

We use high-quality, reusable materials built to endure. Choose based on your industry requirements — from retail display to heavy logistics.

5. Off-the-Shelf vs. Bespoke

If your needs are common, our core range may be just right. For specific challenges, we’ll help you develop a custom solution — even prototyping when needed.

6. Think Long-Term

Reusable boxes are an investment. Consider durability, ease of reuse, and how they integrate into your operations.

Choosing the right box helps your business save money, reduce waste, and elevate your brand. Not sure where to start? Talk to us — we’ll help you find (or create) the perfect fit.