Vyta - IT Lifecycle Solutions

Case Study: Custom Reusable Laptop Storage Boxes for Vyta

When Vyta needed a smarter way to store and transport laptops, cardboard simply wasn’t going to cut it.

Vyta works at the sharp end of IT lifecycle management and secure data destruction. That means high volumes of laptops moving through facilities, across sites and into secure processing environments. Protection, organisation and repeat use are not luxuries. They are operational essentials.

That is where Reusable Box stepped in.

The Brief

Vyta required a durable, stackable and long term storage solution for housing multiple laptops safely in transit and storage.

The boxes needed to:

-

Protect valuable IT assets

-

Withstand repeated handling

-

Stack securely without collapse

-

Offer easy handling for teams on site

-

Maintain a clean, professional branded finish

This was not a one use packaging job. This was infrastructure.

Our Approach

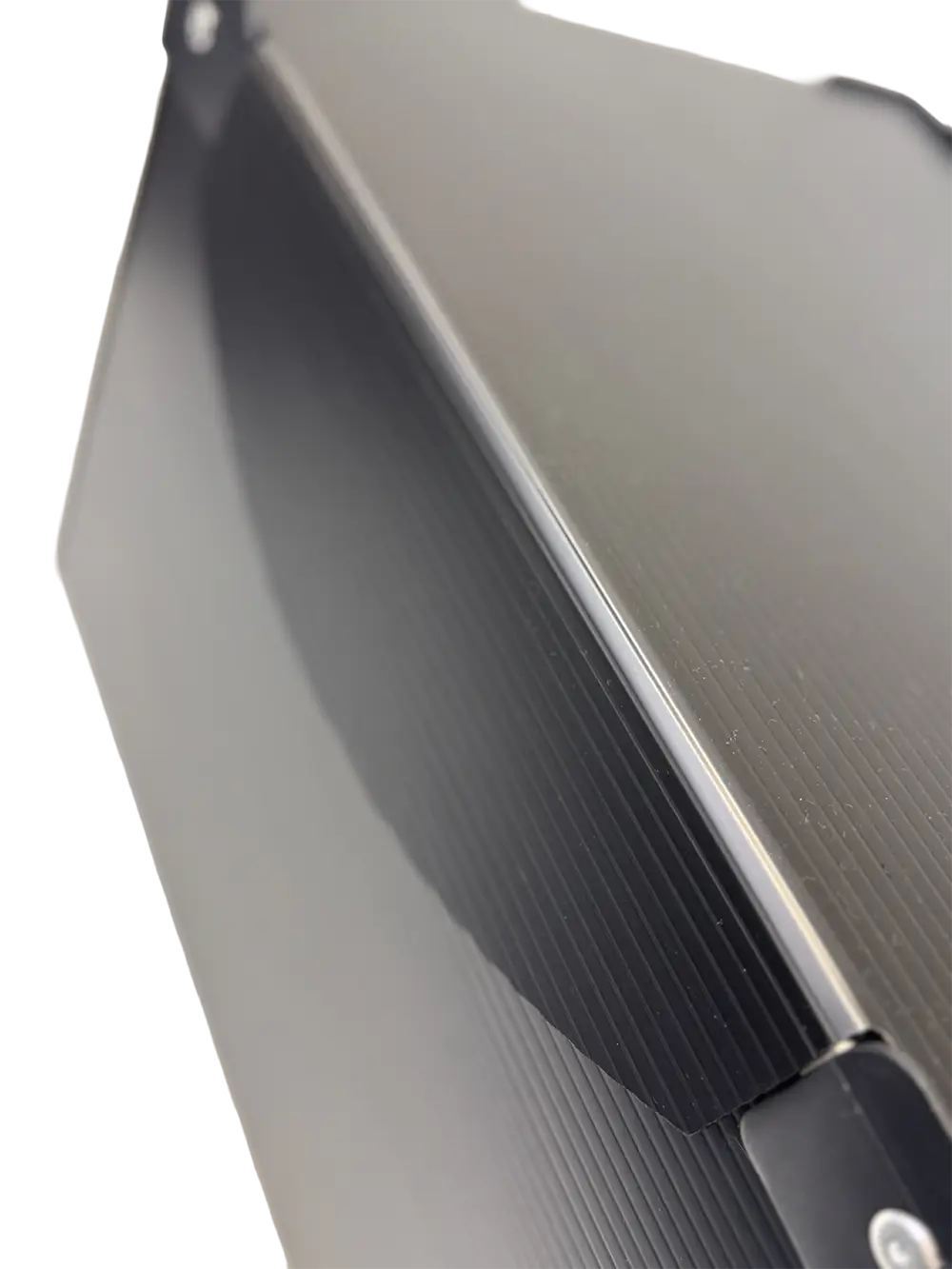

We designed a fully bespoke reusable corrugated plastic box built for strength and repetition.

Key Features:

-

Heavy duty corrugated plastic construction

-

Reinforced riveted corners for structural integrity

-

Integrated carry handles for easy lifting

-

Secure lid with fastening system

-

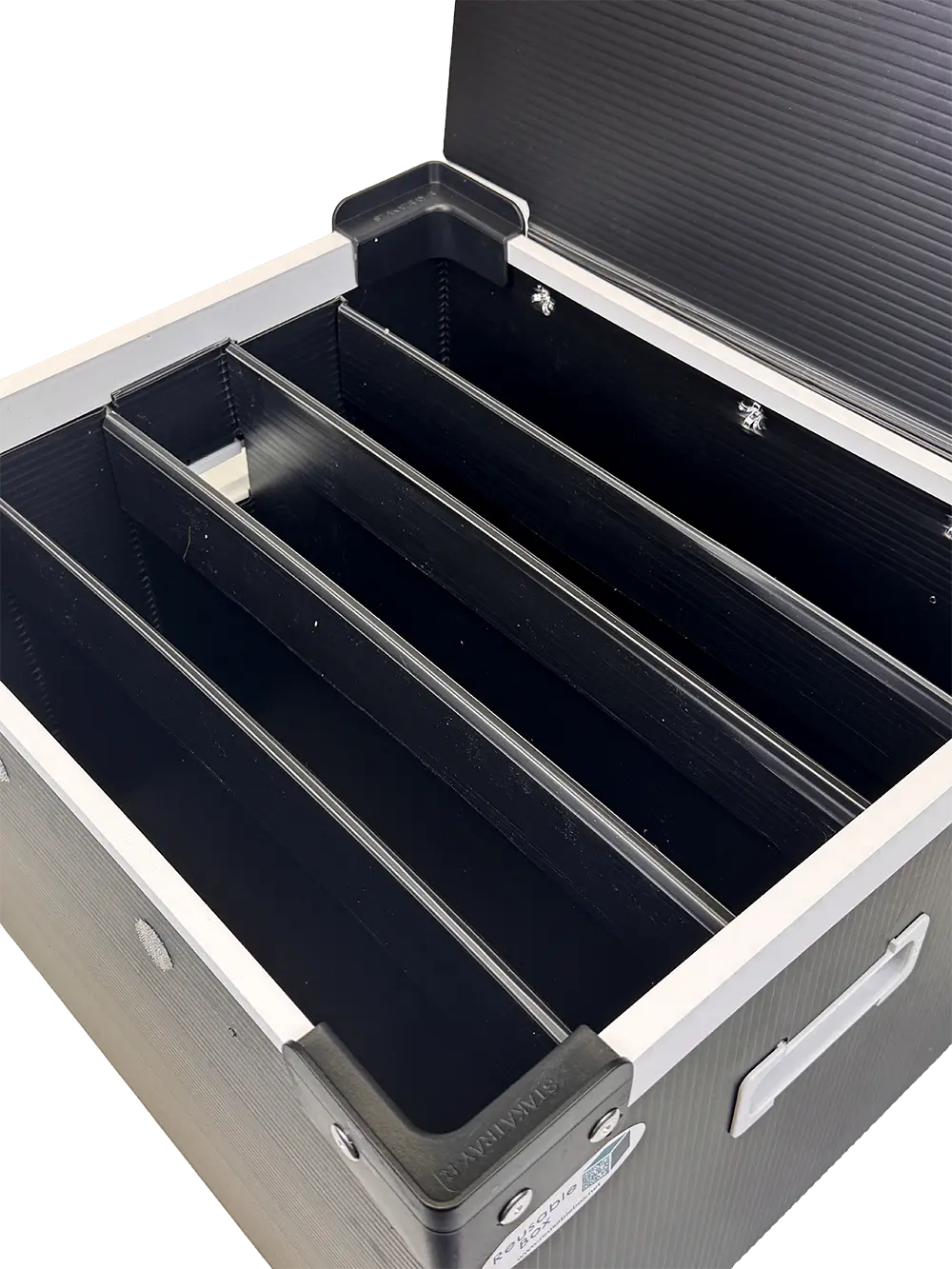

Internal dividers to separate and protect individual laptops

-

Stackable design for efficient warehouse storage

-

Vyta branding applied for a professional finish

These boxes are built to be used again and again, not flattened and forgotten.

The internal dividers were particularly important. Laptops are high value but also high risk if poorly stored. The structured compartments prevent device to device contact, reducing scratches, pressure damage and accidental impact.

The Result

What Vyta now has is not packaging. It is an operational asset.

Instead of cycling through endless cardboard cartons, they have a robust, reusable system that:

-

Reduces damage risk

-

Improves organisation

-

Speeds up handling

-

Cuts long term packaging spend

-

Supports sustainability goals

Stacked high, uniform and secure, these boxes bring order to what could otherwise be a chaotic flow of devices.

For businesses managing large volumes of IT equipment, the right box is not just a container. It is control. It is protection. It is long term cost efficiency disguised as a simple black box.

'The Impossible Box’

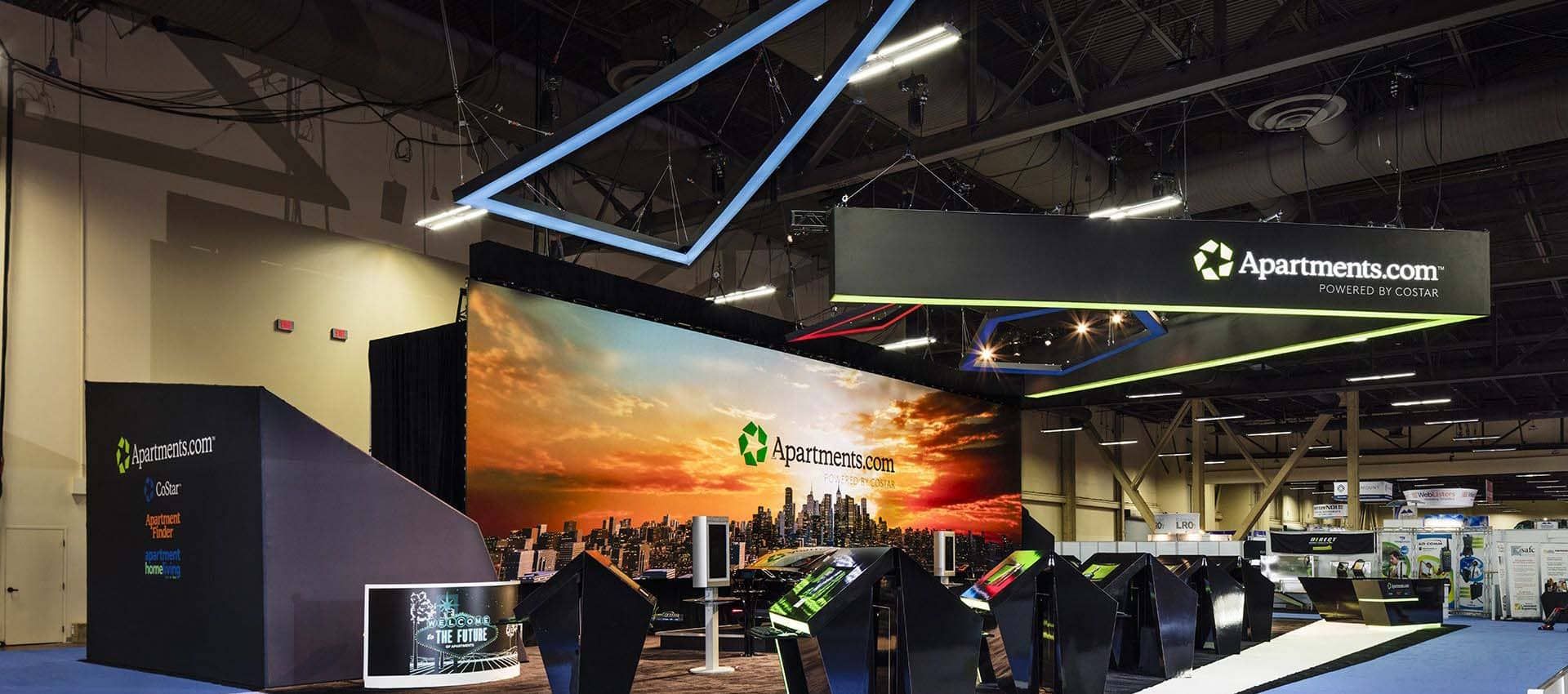

Building the ‘Impossible’ Reusable Box for GSE’s 75 Inch Screens

When GSE in America approached us with a challenge to build a reusable box that could safely transport two 75 inch rental screens, we knew straight away this was no ordinary build. These are huge displays with huge value riding on them. They also needed a solution that was lightweight, strong, shock absorbent, and reusable across multiple hire cycles. A flight case wasn’t suitable and a wooden crate wasn’t practical. What they needed felt like the impossible dream

a reusable box big enough, strong enough, and smart enough to do the job.

So we built it.

To give a sense of scale we even placed a standard 24 inch monitor at the front when we took the photos. It looks like a toy. That is how big this project really is.

From Impossible to Engineered Reality

The first obstacle was size. A single 75 inch screen is large enough. Two screens packed together in one reusable system pushed the design to the edge of what corrugated polypropylene construction can handle. The structure had to remain rigid and square even when empty and still be manageable for the rental teams lifting and loading it.

The second challenge was protection. GSE ship high value screens constantly across events and installations. Their kit gets moved by crews under serious time pressure. The box had to survive being pushed

pulled

slid

manhandled

and still protect the contents.

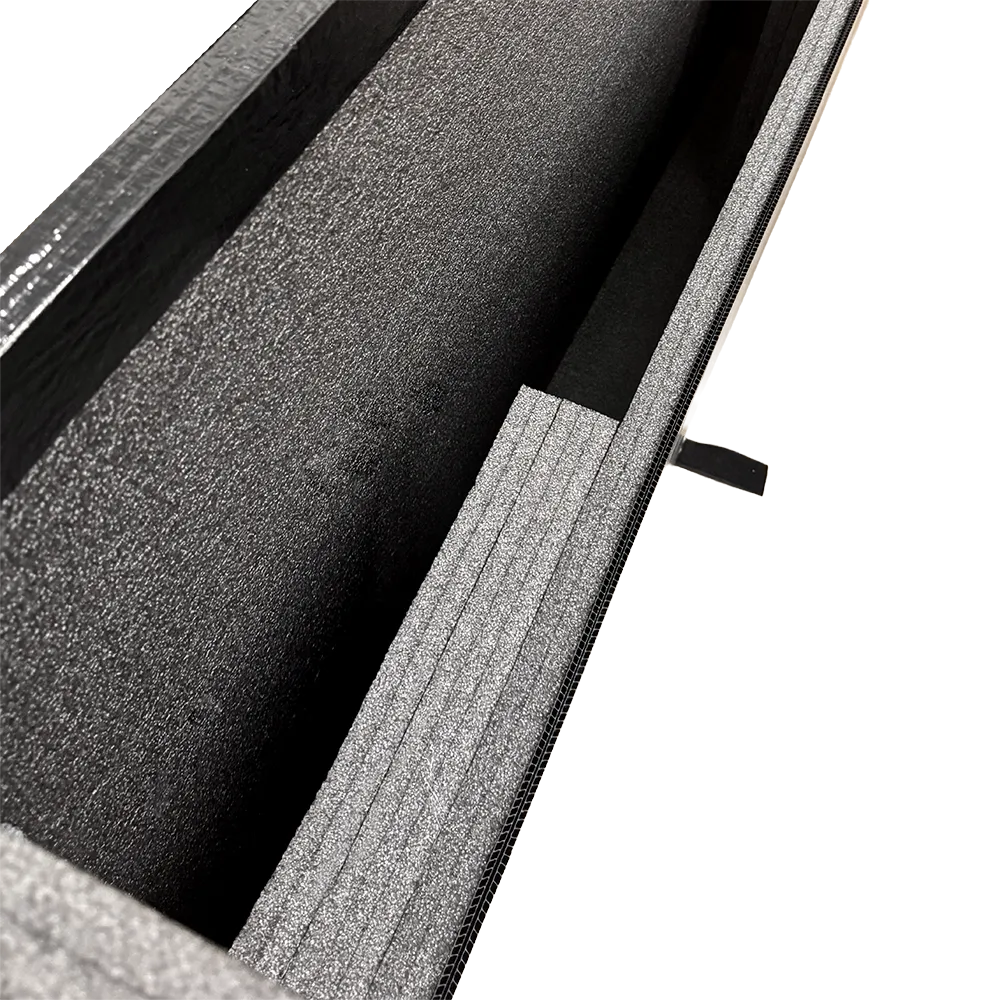

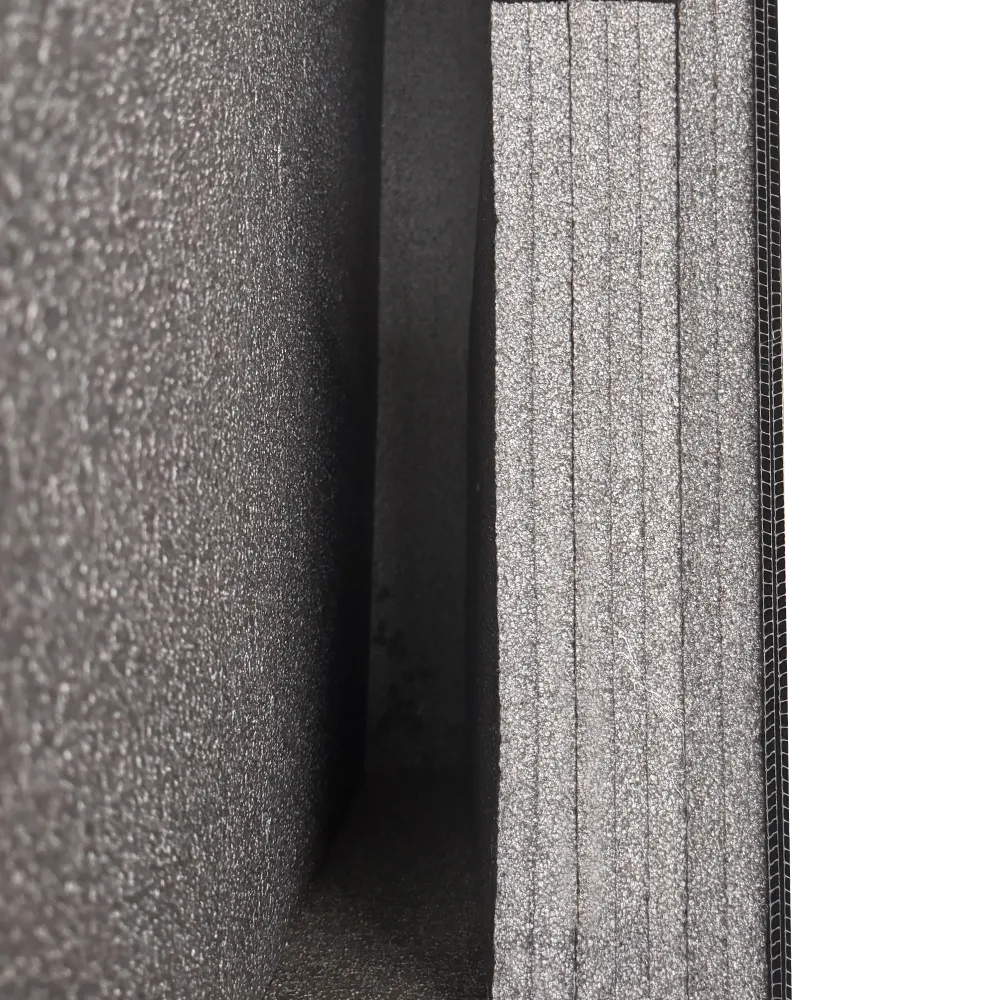

That meant a multi zone foam layout with a floating centre divide, pressure rated sidewalls, a dual depth foam base, and enough shock absorption to cope with hard landings without adding unnecessary bulk.

Designing the Internal Foam System

Inside the box is where the real engineering sits. The foam system is built from multiple layers of 30 kg foam, all precision cut to form a tight structural cradle. There are three key parts:

-

The centre divide that keeps both screens separated and locked in place

-

Sidewall blocks that take lateral impact

-

Base supports that distribute weight evenly

-

Top compression layer that closes the internal system and prevents movement during shipment

Every piece is removable, replaceable, and designed for the realities of rental life.

This is a box that gets used

not admired on a shelf.

Strength Without Weight

We used heavy duty black 10 mm polypropylene for the outer structure, reinforced with both mechanical fixings and internal returns. When you walk around it you realise this isn’t a typical reusable box. It behaves closer to a fully engineered crate while staying lightweight enough for two people to handle.

The side handles, reinforced corners, and pull tabs mean that even though it’s huge, it stays practical in the field.

A Giant in the Workshop

When the prototype stood up in the workshop for the first time it genuinely felt monumental. Everyone who walked past stopped. It is rare for a packaging project to become a talking point

but this one did.

That is why we deliberately photographed it beside a standard 24 inch monitor. It helps people understand the scale of what we were building. You don’t often see a reusable box that towers over desks.

Why GSE Chose Reusable Box

GSE needed:

-

A long lasting solution

-

Better protection than wood or flight cases

-

Weight savings for easier handling

-

Something that could be repaired or re foamed over time

-

A box that could be shipped repeatedly without fail

We delivered all of that while keeping it fully recyclable at end of life.

The Outcome

The final product represents everything reusable packaging should be. Purpose built. Over engineered where it matters. Lightweight where possible. Repairable. Sustainable. And capable of doing what most people would say is impossible.

That’s the part we’re proud of.

This wasn’t just another job

this was solving a problem that no standard case or crate could solve. A reusable box for two monster sized screens that will now travel coast to coast across America with GSE’s rental fleet.

And it all started as the impossible dream.

Custom Foam Inserts: The Hidden Hero in Electronics Storage and Transport

When it comes to protecting sensitive electronics, the container is only half the solution. The unsung hero? Custom foam inserts.

What Are Foam Inserts?

Foam inserts are custom-cut padding that fit precisely around your electronic components inside a reusable box. They prevent movement, absorb impact, and reduce the risk of static or shock damage.

Why They Matter

- Precision Fit: Keeps components locked in place to prevent jostling

- Static Resistance: Available in antistatic and ESD-safe materials

- Modular Use: Easily reorganized for different kits or assemblies

- Damage Reduction: Minimizes risk from vibration, handling, or drops

Use Cases

- Storing populated PCBs and test units

- Transporting R&D samples or high-value modules

- Field engineer kits for service and diagnostics

Cost vs. Value

Though custom inserts add an upfront cost, the long-term value is significant. They reduce product loss, speed up packing, and create a consistent system across your packaging.

Conclusion

Foam inserts enhance the performance of any reusable box, making them essential for any operation handling delicate electronics. They’re not just an add-on—they’re a protective necessity.

Top 5 Mistakes to Avoid When Transporting Sensitive Electronic Components

Transporting sensitive electronic components presents unique challenges. Whether you’re moving items between labs, facilities, or to a customer site, avoiding these five common mistakes can save you from costly delays and product loss.

1. Using Non-ESD-Safe Packaging

Static electricity can destroy sensitive electronics. Avoid using packaging that doesn’t offer ESD protection. Instead, choose antistatic or conductive reusable containers designed specifically for electronics.

2. Inadequate Cushioning

Failing to secure PCBs or modules during transit leads to physical damage. Use foam inserts or custom-cut padding that holds components in place and absorbs shock.

3. Ignoring Environmental Factors

Heat, humidity, and dust can damage electronics. Choose containers that are sealed, water-resistant, and suitable for cleanroom or controlled environments if needed.

4. Poor Labeling and Handling Instructions

Unlabeled or mishandled packages are more likely to be dropped or misplaced. Always label boxes clearly with handling instructions and use barcodes where possible.

5. Relying on Disposable Packaging

Cardboard and bubble wrap are prone to wear and inconsistent protection. Reusable containers provide consistent performance and reduce long-term costs.

Conclusion

By avoiding these common mistakes, you can ensure safe, reliable transportation of sensitive electronic components. Invest in reusable, ESD-safe, and well-cushioned containers for optimal protection.

Why Electronics Manufacturers Are Switching to Reusable Storage Solutions

In today’s fast-paced electronics manufacturing environment, efficiency, sustainability, and protection are top priorities. As a result, many electronics manufacturers are making the shift from single-use packaging to reusable storage boxes.

The Problem with Disposable Packaging

Traditional cardboard boxes and plastic wraps are often single-use, easily damaged, and generate significant waste. For fragile electronic components such as PCBs, semiconductors, and precision modules, this lack of durability can lead to costly damage and downtime.

Reusable Boxes: A Smarter Alternative

Reusable storage boxes made from durable, impact-resistant materials offer better protection and a longer service life. Designed for repeated use, these boxes can withstand the rigors of manufacturing floors and frequent transport.

Key Benefits:

- ESD-safe options to protect against electrostatic discharge

- Foam inserts and dividers to secure delicate components

- Stackable and modular designs for optimized storage

- Long-term cost savings by reducing packaging turnover

Sustainability Matters

With the electronics sector under increasing pressure to reduce environmental impact, reusable packaging plays a key role in sustainability strategies. Less waste, fewer damaged goods, and lower carbon footprints are driving widespread adoption.

Conclusion

Electronics manufacturers that switch to reusable storage solutions gain not only durability and protection but also environmental and financial benefits. As the industry evolves, reusable packaging is becoming the standard for forward-thinking operations.