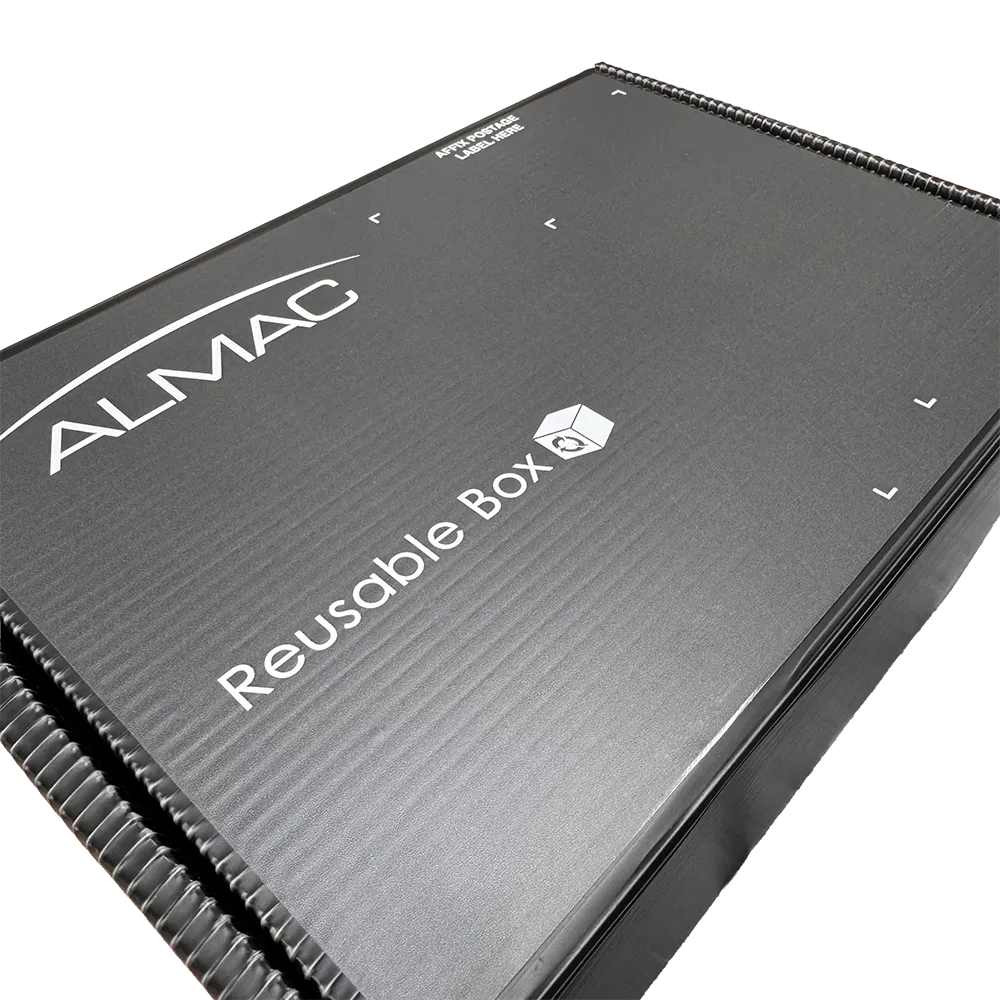

Building Three Custom Reusable Boxes for Almac Pharma

Flexible. Secure. Built for daily movement across a busy pharmaceutical environment.

When Almac Pharmaceuticals approached us, the brief was intentionally loose. They had already used a previous version of our reusable box on site and loved how robust and reliable it was for day to day movement. This time they wanted something more versatile. Instead of one box for one job, they wanted a small family of reusable boxes that could support a wide range of internal transfers across departments, buildings and specialised work areas.

So we designed three different sized boxes with matching foam cushioned inserts for general purpose use throughout their facility.

A Modular Set for Every Task

Pharmaceutical workflows never stand still. Instruments move between labs, testing areas, offices, cleanrooms and storage locations all day long. While the items can change, the demands stay the same: protect the contents, keep everything traceable and make transfers as efficient as possible.

Our solution was to create:

-

A small case for compact instruments, handheld devices and delicate items

-

A medium case for mid sized equipment and testing components

-

A large case built to handle bulkier or multi part items without compromising protection or weight

Each size follows the same structural design so staff can immediately recognise and use them in any department.

Foam Cushioned Inserts for a Flexible Payload

Because Almac needed these boxes for general purpose use, the inserts had to work for many different instruments. Instead of fixed cut outs, we engineered a foam system that gives protection without limiting the shape or size of the payload.

Our 30kg/m³ foam in flexible thicknesses creates a cushioned environment that keeps sensitive items safe during hand carry transfers or trolley movement between buildings.

Security Built Into the Design

Moving instruments inside a busy pharmaceutical environment means security and chain of custody is crucial. Each box includes dedicated locking points for cable ties, allowing staff to seal units quickly and clearly before transfer.

Once the box reaches its destination, the receiving team can confirm that the tie is intact, remove it and continue their workflow with confidence.

Durable and Reusable Across Facilities

All three boxes are built using our heavy duty corrugated polypropylene. It is lightweight, robust and totally water resistant so it stands up to the exact kind of internal transfers pharmaceutical teams carry out every day. From lab corridors to external walkways between buildings, these boxes are designed to last year after year.

A Simple Brief Turned Into a Complete Multi Box Solution

Almac gave us the freedom to design something practical and universal, and the result is a family of reusable boxes that slot seamlessly into their day to day processes. Whether the task is small, medium or large, they now have a consistent protective system that boosts efficiency and safety across their site.

If your organisation needs a similar internal movement solution or a customised version for a specialist workflow, Reusable Box can design it from the ground up.

Case Study: Bespoke Two-Tiered Reusable Box for Almac Pharmaceuticals

Case Study: Bespoke Two-Tiered Reusable Box for Almac Pharmaceuticals

Client: Almac Pharmaceuticals

Sector: Medical & Scientific

Location: Global Operations, Headquartered in Northern Ireland

Overview

Almac Pharmaceuticals, a global leader in pharmaceutical development and manufacturing, approached ReusableBox.net with a packaging challenge. They needed a reliable, reusable solution for transporting sensitive eye drop products equipped with Escort Data Loggers, ensuring both product safety and logistical efficiency.

Challenge

Almac’s logistics team required a packaging solution that could:

-

Securely hold Escort Loggers for temperature-sensitive eye drops

-

Accommodate multiple units while maintaining order and protection

-

Allow for easy return and reuse, in line with their sustainability initiatives

-

Withstand repeated handling through global distribution networks

Standard off-the-shelf packaging was falling short, especially in maintaining product orientation and preventing movement in transit.

Our Solution

We designed and manufactured a custom two-tiered reusable box tailored to Almac’s specific product and handling needs:

Tier 1: Custom Foam Insert for Escort Loggers

-

Precision-cut high-density foam to snugly fit and protect Escort Data Loggers

-

Eye drop containers nestled individually to prevent damage or shifting

-

Easy access design for efficient loading and unloading

Tier 2: Compartment for Boxed Items

-

The second layer was engineered to hold boxed batches of the same products

-

Rigid dividers and stabilisers ensured all items remained secure during transit

-

Layered structure allowed easy separation of monitored and bulk product components

Material & Sustainability

-

Durable plastic outer shell designed for long-term reuse

-

Fully returnable packaging, reducing waste and improving carbon footprint

-

Designed for easy cleaning and sanitisation between cycles

Results

-

Improved Protection: The custom foam prevented movement, protecting sensitive equipment and maintaining calibration integrity.

-

Streamlined Handling: Two-tier design simplified the packing process and product segregation.

-

Cost Efficiency: Reusability reduced Almac’s need for single-use packaging, driving down long-term costs.

-

Sustainability Win: The returnable nature of the boxes aligned with Almac’s green initiatives and reduced packaging waste significantly.

Testimonial

“The reusable solution provided by ReusableBox.net transformed the way we package and transport this product line. It’s secure, robust, and aligns with our ongoing sustainability goals.”

— Logistics Coordinator, Almac Pharmaceuticals

How Reusable Storage Boxes Improve Hygiene Compliance in Labs and Clinics

In clinical and lab environments, hygiene is non-negotiable. Cross-contamination, improper storage, or unsanitised containers can compromise research and patient safety. But disposable packaging isn’t the only option.

Here’s how reusable plastic storage boxes help healthcare and scientific facilities maintain strict hygiene standards while improving operational efficiency.

Key Sections:

1. Why Material Matters in Medical Storage

Reusable plastic boxes are made from non-porous materials that resist bacteria build-up and withstand regular disinfection.

2. Designed for Decontamination

Smooth, sealed surfaces with no sharp internal corners make cleaning easy and effective—perfect for lab and clinical workflows.

3. Reduce Biohazard Waste

Unlike cardboard or Styrofoam, reusable boxes eliminate ongoing packaging waste and the risk of soaking or contamination.

4. Improve Chain-of-Custody with Secure Closures

With tamper-evident lids and label options, you can track samples and supplies safely between departments or sites.

5. Sustainability Meets Compliance

Reusable options support your environmental goals while remaining fully compliant with healthcare storage guidelines.

Efficient Lab Storage: 5 Ways to Optimise Workflow with Stackable Boxes

Lab space is always at a premium. Whether you’re storing reagents, pipettes, sample containers or instruments, clutter and disorganisation slow down research and increase error risk.

Here are five proven ways stackable storage boxes can transform the efficiency of your laboratory.

Key Sections:

1. Free Up Bench Space

Uniform boxes keep storage off the work surface and on shelves, carts, or mobile units.

2. Use Vertical Space Smartly

Stackable containers make the most of limited room, especially in temperature-controlled or sterile zones.

3. Categorise & Label Clearly

Prevent cross-contamination and misplacement with colour-coded or labelled box systems.

4. Improve Transport Between Lab Areas

Need to move samples to cold storage or another facility? Durable boxes make this safe and traceable.

5. Long-Term Cost Benefits

Switching from disposable to reusable containers reduces ordering time and operational waste.